Manst has conducted a deep industrial layout, building a multi-tiered product matrix centered around centralized energy storage as its core business, with industrial and commercial energy storage and user-side energy storage products as its mainstay. Currently, this solution has been successfully applied in diversified scenarios such as comprehensive energy utilization, new energy consumption, peak shaving, demand regulation, and emergency backup power. Its products are exported to over 40 countries and regions worldwide, including Europe, South Asia, and Africa.

-

-

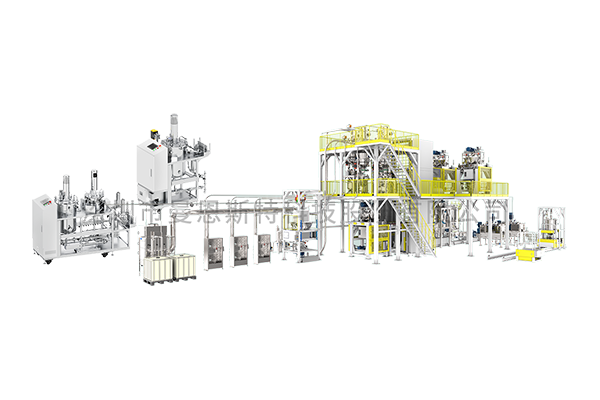

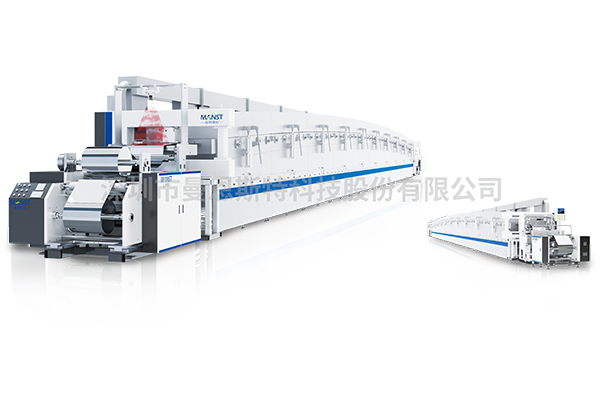

he lithium battery coating technology solution has achieved digital upgrading and intelligent control transformation through the overall design and planning of powder pulping, coating, and rolling processes. In terms of powder pulping, intelligent scheduling and multi-stage dual support ceramic twin-screw continuous pulping technology are adopted, greatly improving production efficiency and pulping quality. In terms of coating, closed-loop control is introduced to adjust surface density, infrared drying, NMP local recovery, and polar data traceability system, achieving efficient coating process control and energy consumption reduction. Meanwhile, in the rolling process, thickness closed-loop control technology is adopted to ensure product consistency and quality.

-

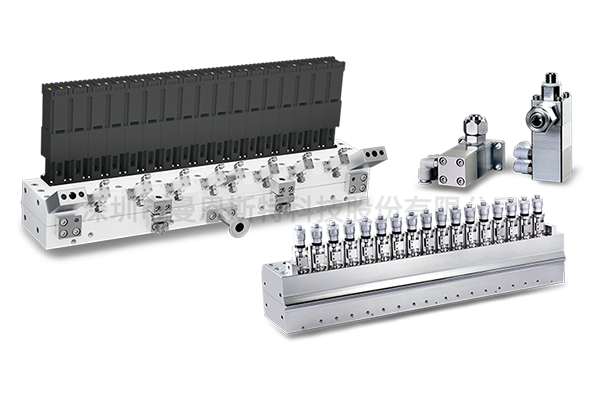

Manst focuses on the field of coating technology, starting from customer product pain points and process innovation, and has successively developed a variety of coating head product matrices that match customer needs. It can provide personalized selection of various adjustment methods, single-layer multi slurry, multi-layer coating, and coating die products of different materials.

-

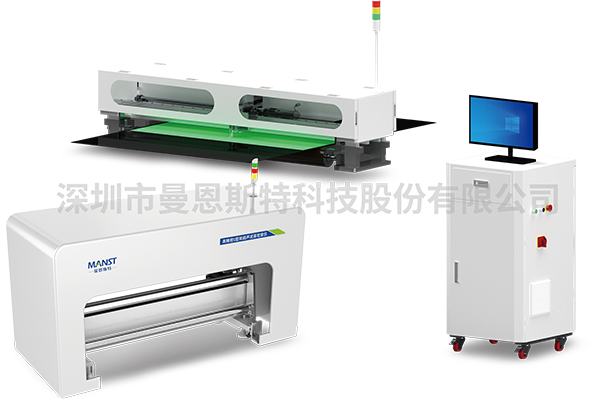

When ultrasonic waves penetrate a medium, part of the sound wave isabsorbed by the medium. Resulting in the penetration of the mediumafter the intensity of the sound wave relative to the intensity of theincident acoustic wave has a certain attenuation. The attenuation ratioand the surface density of the penetrated medium have a negativeexponential relationship. The surface density of the medium can bededuced from the attenuation of the acoustic wave intensity before andafter the acoustic wave penetrates the medium detected by thereceiving device.

-

Relying on years of technical precipitation in the field of coating technology, Manst helps localization of chip equipment and accelerates the landing and cost reduction of perovskite photovoltaic; through flat slot die-coating system, PVD coating and other film-forming methods, we enhance the localization rate of film-making equipment and help perovskite solar cells move from laboratory to large-area industrial production.

-

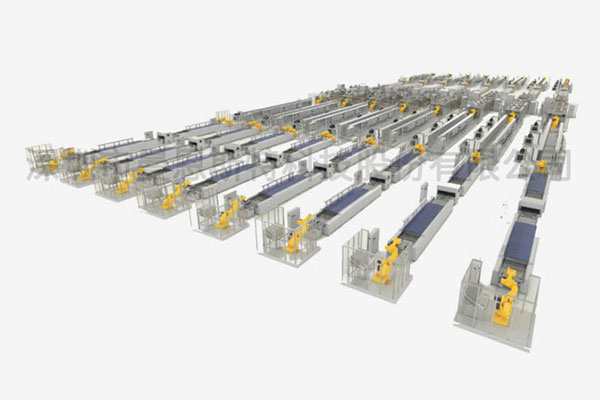

Solutions for hydrogen fuel smart manufacturing: By designing a series of complete systems such as intelligent production line, data analysis system, Internet of Things and safety management system, combined with a variety of technical means and management methods, we can achieve higher production efficiency, quality assurance, environmental improvement and safety assurance.

-

Manst has increased its R&D investment in the powder drying process in the early stage. Through a series of innovations, it has developed a new generation of spray drying units, double-support single-cone vacuum drying units, high-temperature single-cone dryers, and other products, which reduce energy consumption, improve production efficiency, extend equipment lifespan, and reduce costs, thereby facilitating the upgrading of battery manufacturing.

-

Manst Fluid Technology Co., Ltd. specializes in industrial environmental protection dust removal, solid-liquid separation and filtration. Its main products include cartridge filter elements, pleated filter elements, wound filter elements, dust removal filter cartridges, dust removal bags, etc. It can provide overall solutions for filtration, separation and purification for customers in various industries.