Laser Metrology System

Laser Metrology SystemLaser measurement system utilizes triangulation principle with dual high-precision laser displacement sensors coaxially mounted in opposition within upper/lower arms of a transversely traversing C-frame carriage, enabling online non-contact thickness metrology for lithium electrode coating layers and taper zones during coating/slitting/winding processes, as well as thickness inspection for metal foils, films, sheets and plates in general material industries.

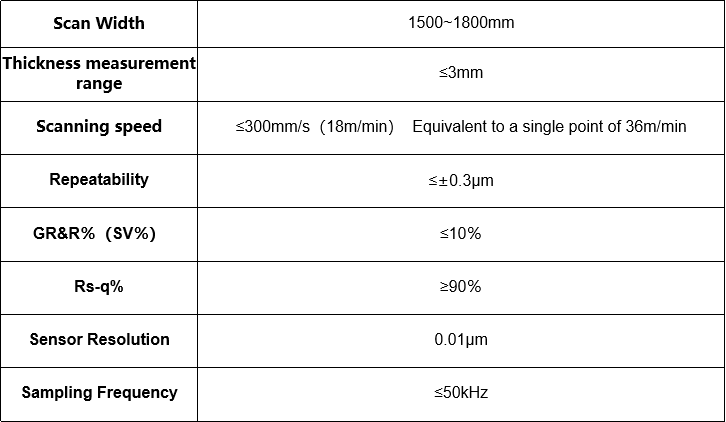

Dual-Head Horizontal Thickness GaugeThe monolithic O-frame scanner strategically distributes the measurement stroke required for wide-web scanning to dual-sensor groups, effectively halving individual sensor travel. This design shortens cantilever mounting length, mitigates deflection-induced vibration, and enhances measurement accuracy. Specifically engineered for lithium-ion battery electrode calendaring processes, this solution delivers precision thickness measurement for ultra-wide electrodes (1500~1800mm).Detailed Introduction

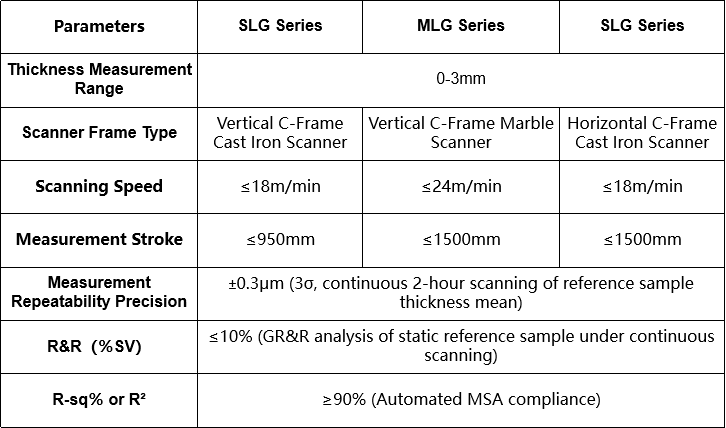

Dual-Head Horizontal Thickness GaugeThe monolithic O-frame scanner strategically distributes the measurement stroke required for wide-web scanning to dual-sensor groups, effectively halving individual sensor travel. This design shortens cantilever mounting length, mitigates deflection-induced vibration, and enhances measurement accuracy. Specifically engineered for lithium-ion battery electrode calendaring processes, this solution delivers precision thickness measurement for ultra-wide electrodes (1500~1800mm).Detailed Introduction Laser Real-Time Thickness GaugeThis thickness gauge employs triangulation via dual coaxially opposed high-precision laser displacement sensors mounted in upper/lower arms of a transversely traversing C-frame. With laser spacing D₀, upper sensor measuring displacement D₁ to the electrode surface, and lower sensor measuring displacement D₂ to the opposite surface, the geometric thickness T is calculated as T = D₀ - D₁ - D₂. The system enables online non-contact thickness metrology for lithium electrode coating layers and taper zones during coating/slitting/winding processes, while also serving thickness inspection needs for metal foils, films, sheets, and plates across material industries.Detailed Introduction

Laser Real-Time Thickness GaugeThis thickness gauge employs triangulation via dual coaxially opposed high-precision laser displacement sensors mounted in upper/lower arms of a transversely traversing C-frame. With laser spacing D₀, upper sensor measuring displacement D₁ to the electrode surface, and lower sensor measuring displacement D₂ to the opposite surface, the geometric thickness T is calculated as T = D₀ - D₁ - D₂. The system enables online non-contact thickness metrology for lithium electrode coating layers and taper zones during coating/slitting/winding processes, while also serving thickness inspection needs for metal foils, films, sheets, and plates across material industries.Detailed Introduction