Edge Trimming Module

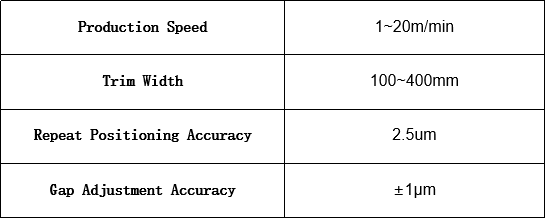

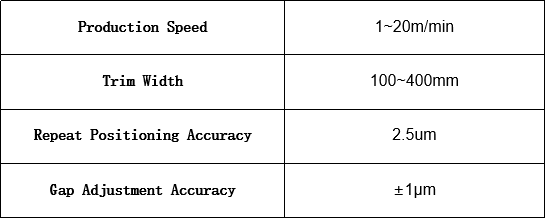

Edge Trimming ModuleThe trimming module performs electrode shaping in coordination with film-forming equipment. As Mannster's process involves direct in-line film formation and compounding on rollers, trimming must occur on-roll. Current solutions comprise two methods: non-metallic blade full-cut systems and non-contact metallic blade partial-cut systems—selection depends on critical parameters; non-metallic full-cut delivers superior edge straightness for precision applications, while metallic partial-cut preserves roller surface integrity via contactless operation.

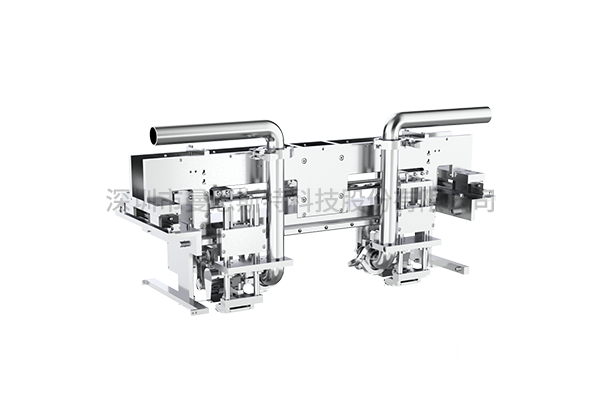

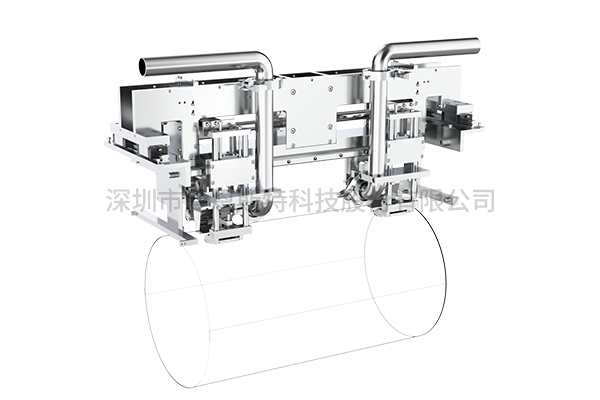

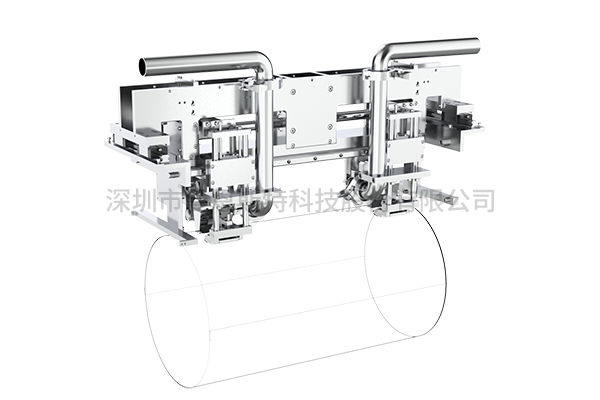

On‑roll Metallic Partial‑Cut Solution (Circular Blade)The trimming mechanism comprises a cutting module, an adjustment module, and a scrap removal module. It trims the film edges, collects waste material, and ensures the film is neatly aligned with the foil during lamination. The system is compatible with both on‑roll non‑metallic full‑cut and metallic partial‑cut operating modes.Detailed Introduction

On‑roll Metallic Partial‑Cut Solution (Circular Blade)The trimming mechanism comprises a cutting module, an adjustment module, and a scrap removal module. It trims the film edges, collects waste material, and ensures the film is neatly aligned with the foil during lamination. The system is compatible with both on‑roll non‑metallic full‑cut and metallic partial‑cut operating modes.Detailed Introduction On‑roll Non‑Metallic Full‑Cut Solution (Circular Blade)The trimming mechanism consists of a cutting module, an adjustment module, and a scrap removal module. It trims the film edges and collects the waste material, ensuring neat alignment with the foil during lamination. This mechanism is compatible with both non-metallic full-cut and metallic partial-cut operation modes on the roll.Detailed Introduction

On‑roll Non‑Metallic Full‑Cut Solution (Circular Blade)The trimming mechanism consists of a cutting module, an adjustment module, and a scrap removal module. It trims the film edges and collects the waste material, ensuring neat alignment with the foil during lamination. This mechanism is compatible with both non-metallic full-cut and metallic partial-cut operation modes on the roll.Detailed Introduction

- Add:

NO.3, Zhukeng Third Industrial Zone, Jinniu East Road, Pingshan District, Shenzhen

- Tel:

0755-89369630

- Mob:

400-822-5968

- E-mail:

brand@sz-manst.com

-

Wechat

Wechat -

Channels

Channels -

Duoyin

Duoyin