Film Forming and Calendering Module

Film Forming and Calendering ModuleThe calendering module, as the core process equipment for dry electrodes, directly determines film quality. Mannster has developed market-driven solutions including: triple-roll calendering film formers, quadruple-roll composite film formers, quintuple-roll composite film formers, sextuple-roll composite film formers, and industry-first 14-roll double-sided calendering systems. The quintuple-roll unit currently deployed in our Dry Process Lab serves as the primary platform for internal and external dry process testing, research, and development—establishing the industry benchmark for precision film formation.

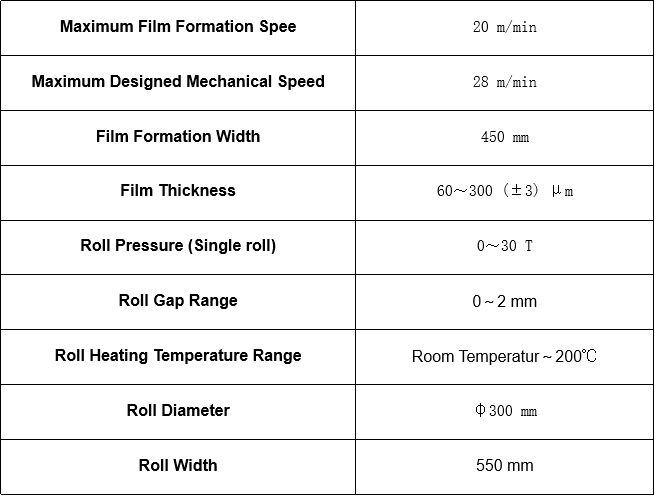

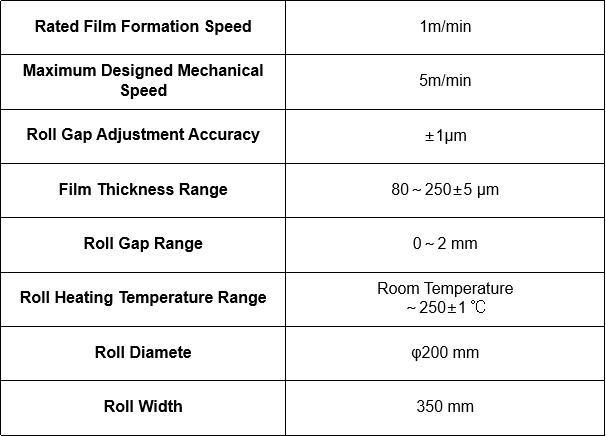

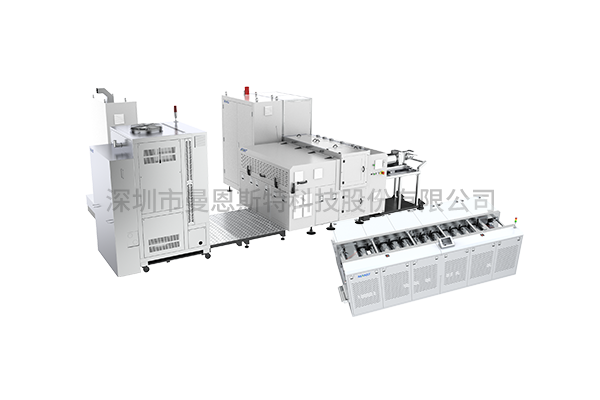

Fourteen-Roll Single-Sided Film Formation & Lamination Integrated MachineThe Fourteen-Roll Double-Dided Film Formation & Lamination Integrated Machine employs a parallel fourteen-roll continuous rolling technology. By precisely adjusting roll gaps, pressure, and temperature, multi-stage calendering and film forming are achieved. This technology enables efficient control over film thickness, ensures consistent product quality, and meets diverse production requirements.Detailed Introduction

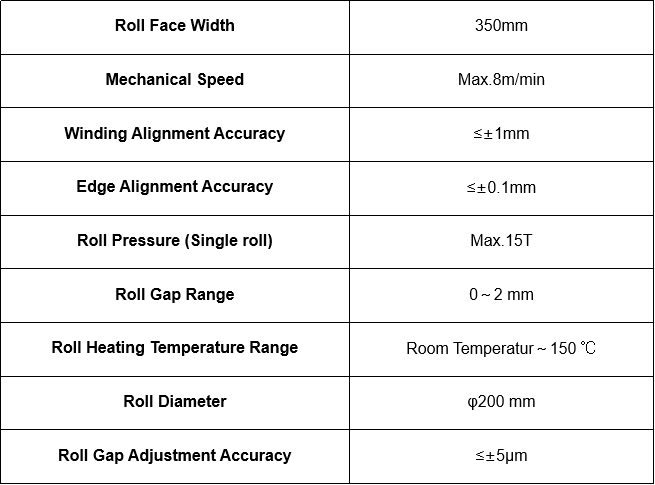

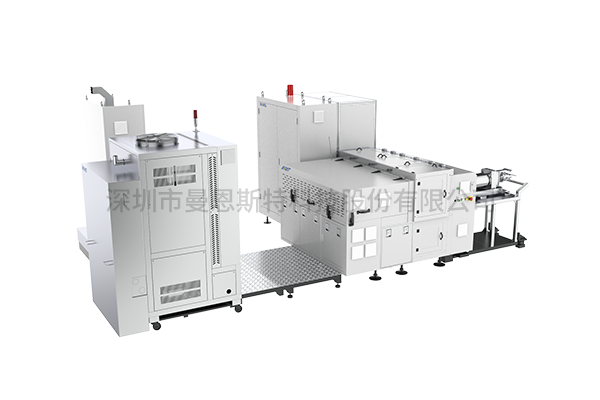

Fourteen-Roll Single-Sided Film Formation & Lamination Integrated MachineThe Fourteen-Roll Double-Dided Film Formation & Lamination Integrated Machine employs a parallel fourteen-roll continuous rolling technology. By precisely adjusting roll gaps, pressure, and temperature, multi-stage calendering and film forming are achieved. This technology enables efficient control over film thickness, ensures consistent product quality, and meets diverse production requirements.Detailed Introduction Six-Roll Single-Sided Film Formation & Lamination Integrated MachineThe Dry-Process Single-Sided Electrode Film Formation & LaminationIntegrated Machine is a highly efficient and automated production equipment for battery electrodes. It integrates essential functions including film forming, calendering, laminating, winding, and unwinding. Through precise control, it ensures uniformity and consistency of the electrodes. Furthermore, the device supports configuration upgrades, such as the addition of feeding modules and thickness measurement units, to further enhance production efficiency and product quality.Detailed Introduction

Six-Roll Single-Sided Film Formation & Lamination Integrated MachineThe Dry-Process Single-Sided Electrode Film Formation & LaminationIntegrated Machine is a highly efficient and automated production equipment for battery electrodes. It integrates essential functions including film forming, calendering, laminating, winding, and unwinding. Through precise control, it ensures uniformity and consistency of the electrodes. Furthermore, the device supports configuration upgrades, such as the addition of feeding modules and thickness measurement units, to further enhance production efficiency and product quality.Detailed Introduction Five-Roll Single-Sided Film Formation & Lamination Integrated MachineThe Single-Side Film Laminating & Composite Integrated Machine integrates functions including unwinding, splicing, dancer roll control, tension measurement, active roll lamination, and automatic winding. It achieves efficient bonding of the current collector with the film, automatically winding the composite into appropriately sized electrode film rolls while ensuring precise and stable lamination throughout the process.Detailed Introduction

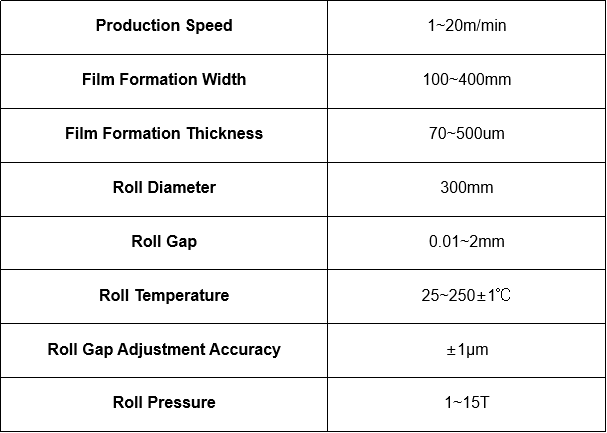

Five-Roll Single-Sided Film Formation & Lamination Integrated MachineThe Single-Side Film Laminating & Composite Integrated Machine integrates functions including unwinding, splicing, dancer roll control, tension measurement, active roll lamination, and automatic winding. It achieves efficient bonding of the current collector with the film, automatically winding the composite into appropriately sized electrode film rolls while ensuring precise and stable lamination throughout the process.Detailed Introduction Four-Roll Film Forming MachineThe Four-Roll Experimental Film Formation & Thinning Machine is an integrated equipment used in dry process technology for film formation, thinning, and thermal lamination of electrode and electrolyte composite powders onto current collectors. It mainly consists of a frame unit, a roll pressing unit, and a gap adjustment unit. During operation, the electrode powder mixture passes through multiple heated rolls, where it is progressively calendered into a continuous film with precise thickness control, and is finnally thermally bonded onto the current collector.

Four-Roll Film Forming MachineThe Four-Roll Experimental Film Formation & Thinning Machine is an integrated equipment used in dry process technology for film formation, thinning, and thermal lamination of electrode and electrolyte composite powders onto current collectors. It mainly consists of a frame unit, a roll pressing unit, and a gap adjustment unit. During operation, the electrode powder mixture passes through multiple heated rolls, where it is progressively calendered into a continuous film with precise thickness control, and is finnally thermally bonded onto the current collector.

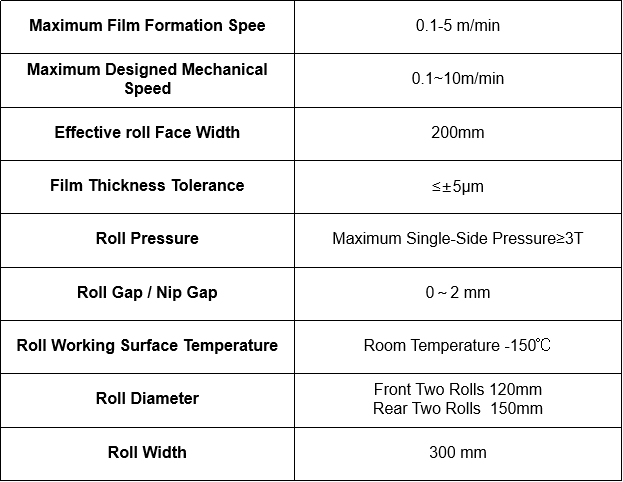

Detailed Introduction Three-Roll Film Forming MachineThe three-roll system utilizes three coordinated rolls to apply controlled pressure and temperature, compressing the fibrillated material into a uniform thin layer. As the rolls rotate, the layer gradually cools and solidifies into a continuous film. The solidified film is then trimmed and wound into rolls by a take-up mechanism.Detailed Introduction

Three-Roll Film Forming MachineThe three-roll system utilizes three coordinated rolls to apply controlled pressure and temperature, compressing the fibrillated material into a uniform thin layer. As the rolls rotate, the layer gradually cools and solidifies into a continuous film. The solidified film is then trimmed and wound into rolls by a take-up mechanism.Detailed Introduction

- Add:

NO.3, Zhukeng Third Industrial Zone, Jinniu East Road, Pingshan District, Shenzhen

- Tel:

0755-89369630

- Mob:

400-822-5968

- E-mail:

brand@sz-manst.com

-

Wechat

Wechat -

Channels

Channels -

Duoyin

Duoyin