Feeding Module

Feeding ModuleThe feeding module serves as auxiliary equipment for film-forming material supply. Mannster has engineered four core systems: steel-belt pre-film formers, counter-roller pre-film formers, powder dispensing feeders, and vibration feeders. Powder dispensing feeders automate traditional manual powder spreading; steel-belt and counter-roller systems resolve industry-wide defects of uneven distribution and poor film formation—delivering industry-leading solutions; vibration feeders enable real-time adjustable lateral powder distribution, subsequently integrating with areal density detection to achieve closed-loop control for dry electrode film formation.

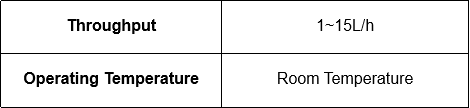

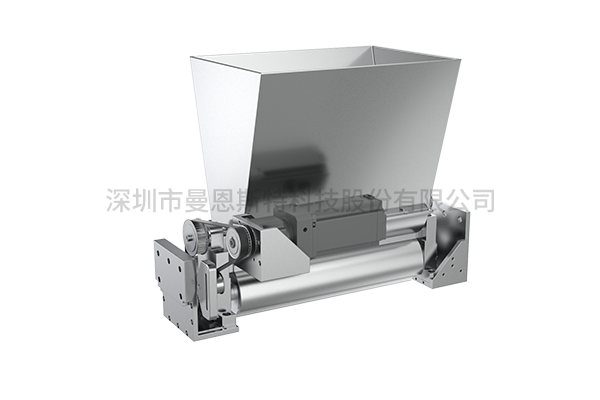

Vibratory FeedingBy utilizing a vibration mechanism, an electric actuator, and a distance sensor, closed-loop control is achieved. This enables stable, metered, and fully automatic material feeding, meeting the material handling requirements of various industries.Detailed Introduction

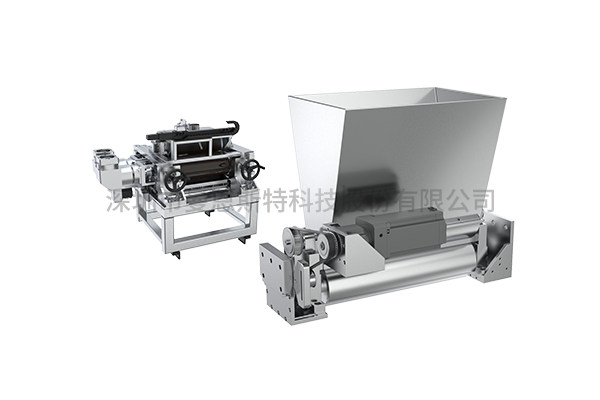

Vibratory FeedingBy utilizing a vibration mechanism, an electric actuator, and a distance sensor, closed-loop control is achieved. This enables stable, metered, and fully automatic material feeding, meeting the material handling requirements of various industries.Detailed Introduction Powder DispensingPowder is applied onto the roll via a metering roll, which quantitatively dispenses the fibrillated powder material into the roll gap, while a scraper cleans the surface of the metering roll.Detailed Introduction

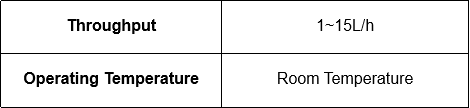

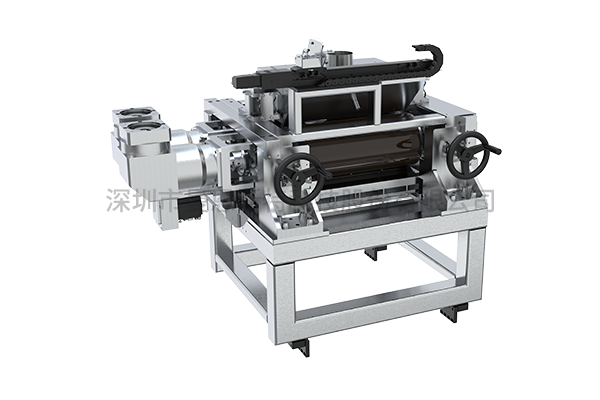

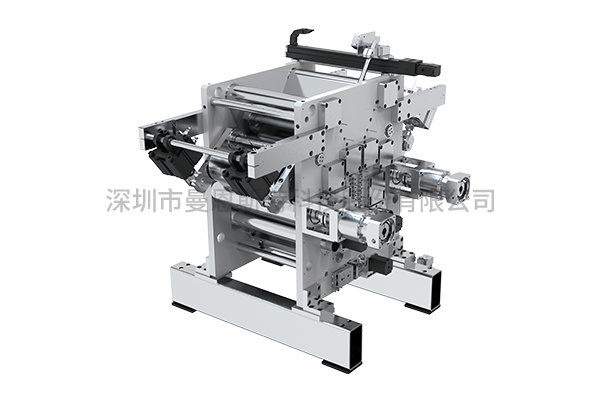

Powder DispensingPowder is applied onto the roll via a metering roll, which quantitatively dispenses the fibrillated powder material into the roll gap, while a scraper cleans the surface of the metering roll.Detailed Introduction Roll-to-Roll Pre-forming SystemThe process utilizes two electromagnetic heating rolls that rotate in opposite directions, with one of the rolls additionally performing axial reciprocating motion. This mechanism compresses the fibrillated powder material into a pre-formed sheet, achieving a preliminary film of specified thickness. This step prepares the material for subsequent calendering and thinning operations, while maximizing the consistency of areal density and thickness in the final film.Detailed Introduction

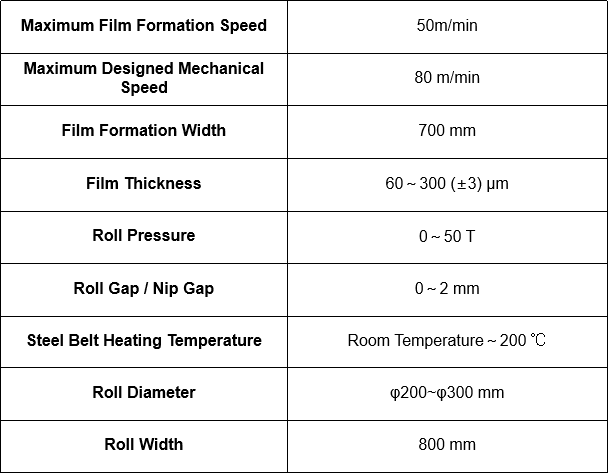

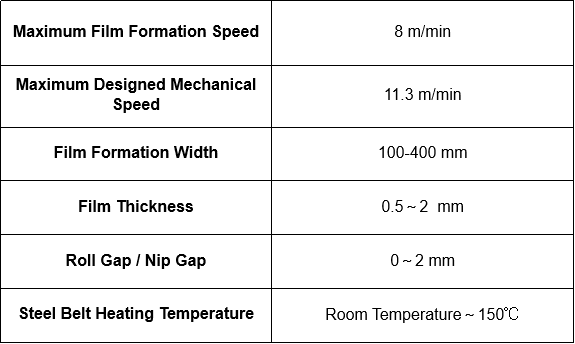

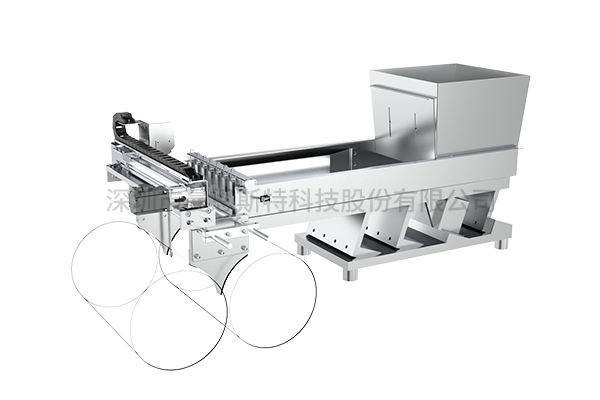

Roll-to-Roll Pre-forming SystemThe process utilizes two electromagnetic heating rolls that rotate in opposite directions, with one of the rolls additionally performing axial reciprocating motion. This mechanism compresses the fibrillated powder material into a pre-formed sheet, achieving a preliminary film of specified thickness. This step prepares the material for subsequent calendering and thinning operations, while maximizing the consistency of areal density and thickness in the final film.Detailed Introduction Steel Belt Pre-forming SystemThe steel belt pre-forming unit pre-compacts electrodel powder into a thick film sheet and delivers metered, continuous, and stable feeding to the multi-roll calendering and thinning equipment. The unit uses two symmetrically arranged endless steel belts that continuously convey powder into a wedge-shaped outlet. As the powder passes through this gradually narrowing gap, its volume is progressively reduced until it is compacted into a film. This wedge-shaped mechanism significantly increases film compaction density while improving thickness and density uniformity.Detailed Introduction

Steel Belt Pre-forming SystemThe steel belt pre-forming unit pre-compacts electrodel powder into a thick film sheet and delivers metered, continuous, and stable feeding to the multi-roll calendering and thinning equipment. The unit uses two symmetrically arranged endless steel belts that continuously convey powder into a wedge-shaped outlet. As the powder passes through this gradually narrowing gap, its volume is progressively reduced until it is compacted into a film. This wedge-shaped mechanism significantly increases film compaction density while improving thickness and density uniformity.Detailed Introduction

- Add:

NO.3, Zhukeng Third Industrial Zone, Jinniu East Road, Pingshan District, Shenzhen

- Tel:

0755-89369630

- Mob:

400-822-5968

- E-mail:

brand@sz-manst.com

-

Wechat

Wechat -

Channels

Channels -

Duoyin

Duoyin