Fibrillation Module

Fibrillation ModuleFibrillation quality fundamentally determines the film-forming capability and performance of dry electrodes as the core process. Mannster has developed diversified fibrillation equipment: pneumatic fibrillators primarily process anode materials with low-specific-gravity particles; high-intensity mixers deliver integrated mixing and fibrillation with optimal cost-effectiveness; high-speed mixers enable micro-scale laboratory operations; twin-screw extruders accommodate high-throughput mass production—collectively addressing multifaceted industrial demands.

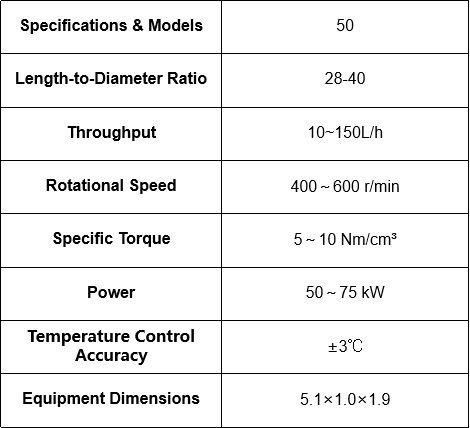

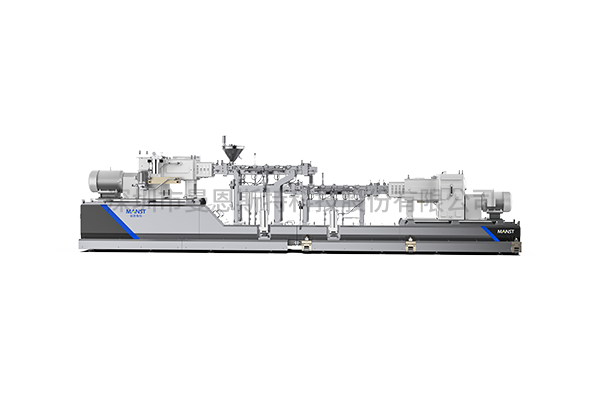

The Dry Twin-Screw ExtruderThe Dry Twin-Screw Extruder is a processing equipment used in multiple industries. Its high-efficency mixing, homogenization, and dispersion capabilities make it particularly valuable in the mixing processes for next-generation lithium-ion batteries.Detailed Introduction

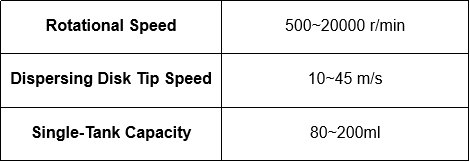

The Dry Twin-Screw ExtruderThe Dry Twin-Screw Extruder is a processing equipment used in multiple industries. Its high-efficency mixing, homogenization, and dispersion capabilities make it particularly valuable in the mixing processes for next-generation lithium-ion batteries.Detailed Introduction The High-Speed DisperserThe High-Speed Disperser is a key equipment for slurry fibrillation, integrating a machine base, motor, dispersion unit, and vacuum/cooling systems. Driven by the motor, the dispersion blades rotate at high speed to achieve efficient dispersion and fibrillation of the slurry, while ensuring vacuum and cooling requirements during the process.Detailed Introduction

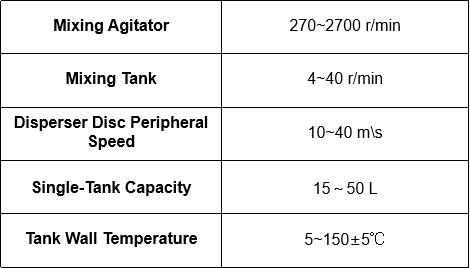

The High-Speed DisperserThe High-Speed Disperser is a key equipment for slurry fibrillation, integrating a machine base, motor, dispersion unit, and vacuum/cooling systems. Driven by the motor, the dispersion blades rotate at high speed to achieve efficient dispersion and fibrillation of the slurry, while ensuring vacuum and cooling requirements during the process.Detailed Introduction Intensive MixerIntensive Mixer is a high-performance and versatile mixing machine capable of operating in either counter-current or cross-flow mixing modes. It meets the precise demands of batch production while also supporting high-throughput continuous operation. Equipped with advanced processing technology, the Intensive Mixer effortlessly handles various complex and specialized mixing and fibrillation tasks in modern production, ensuring uniform powder dispersion and fibrillation for a wide range of industrial applications.Detailed Introduction

Intensive MixerIntensive Mixer is a high-performance and versatile mixing machine capable of operating in either counter-current or cross-flow mixing modes. It meets the precise demands of batch production while also supporting high-throughput continuous operation. Equipped with advanced processing technology, the Intensive Mixer effortlessly handles various complex and specialized mixing and fibrillation tasks in modern production, ensuring uniform powder dispersion and fibrillation for a wide range of industrial applications.Detailed Introduction

- Add:

NO.3, Zhukeng Third Industrial Zone, Jinniu East Road, Pingshan District, Shenzhen

- Tel:

0755-89369630

- Mob:

400-822-5968

- E-mail:

brand@sz-manst.com

-

Wechat

Wechat -

Channels

Channels -

Duoyin

Duoyin