Mixing Module

Mixing ModuleDry powder uniformity critically governs the areal density and tension profile of resultant electrode sheets, constituting the primary process in dry-process manufacturing. Mannster has engineered mixing equipment for diverse applications: dual-motion mixers achieve superior blending homogeneity; high-intensity mixers integrate mixing with pre-fibrillation at optimal cost-performance for experimental applications; high-speed mixers facilitate micro-scale laboratory processing; VC blending systems accommodate mass production demands—collectively catering to multifaceted operational requirements.

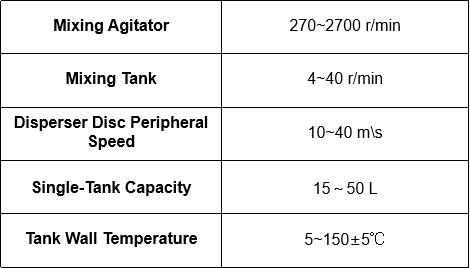

Intensive MixerIntensive Mixer is a high-performance and versatile mixing machine capable of operating in either counter-current or cross-flow mixing modes. It meets the precise demands of batch production while also supporting high-throughput continuous operation. Equipped with advanced processing technology, the Intensive Mixer effortlessly handles various complex and specialized mixing and fibrillation tasks in modern production, ensuring uniform powder dispersion and fibrillation for a wide range of industrial applications.Detailed Introduction

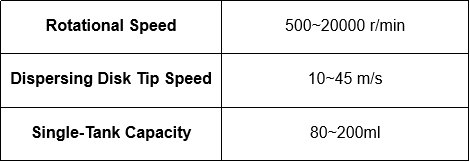

Intensive MixerIntensive Mixer is a high-performance and versatile mixing machine capable of operating in either counter-current or cross-flow mixing modes. It meets the precise demands of batch production while also supporting high-throughput continuous operation. Equipped with advanced processing technology, the Intensive Mixer effortlessly handles various complex and specialized mixing and fibrillation tasks in modern production, ensuring uniform powder dispersion and fibrillation for a wide range of industrial applications.Detailed Introduction The High-Speed DisperserThe High-Speed Disperser is a key equipment for slurry fibrillation, integrating a machine base, motor, dispersion unit, and vacuum/cooling systems. Driven by the motor, the dispersion blades rotate at high speed to achieve efficient dispersion and fibrillation of the slurry, while ensuring vacuum and cooling requirements during the process.Detailed Introduction

The High-Speed DisperserThe High-Speed Disperser is a key equipment for slurry fibrillation, integrating a machine base, motor, dispersion unit, and vacuum/cooling systems. Driven by the motor, the dispersion blades rotate at high speed to achieve efficient dispersion and fibrillation of the slurry, while ensuring vacuum and cooling requirements during the process.Detailed Introduction The VC High-Efficiency MixerThe VC High-Efficiency Mixer lifts materials upward using blades located at the shaft core. As the materials pass through the high-speed chopper assembly, they are thoroughly mixed and dispersed. Under gravity, the dispersed materials fall back to the bottom of the chamber, where they undergo secondary mixing and dispersion by high-speed agitator during the descent. Through multiple iterations of mixing and dispersion, the materials achieve the uniformity and quality required by the customer.

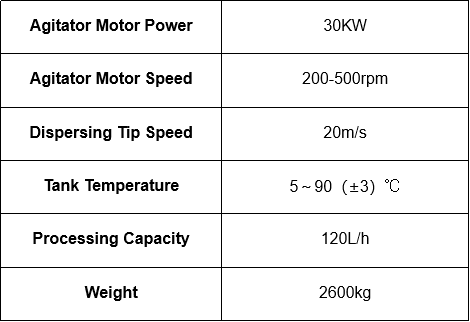

The VC High-Efficiency MixerThe VC High-Efficiency Mixer lifts materials upward using blades located at the shaft core. As the materials pass through the high-speed chopper assembly, they are thoroughly mixed and dispersed. Under gravity, the dispersed materials fall back to the bottom of the chamber, where they undergo secondary mixing and dispersion by high-speed agitator during the descent. Through multiple iterations of mixing and dispersion, the materials achieve the uniformity and quality required by the customer.

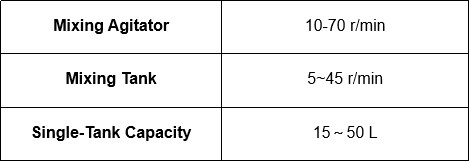

With its ultra-high-speed mixing and dispersing capability and dual-support design, the VC High-Efficiency Mixer is well suited for intensive mixing, dispersion, and coating applications involving slurries, liquids, and powders.Detailed Introduction A Dual-Motion MixerA Dual-Motion Mixer is a highly efficient and versatile mixing machine that integrates three mixing mechanisms — convection, diffusion, and shearing — which enables the highly efficient and uniform mixing of powder materials. Through precise control of the internal motion trajectory of the mixer, it effectively enhances mixing performance and meets the process requirements of a wide range of industrial applications.

A Dual-Motion MixerA Dual-Motion Mixer is a highly efficient and versatile mixing machine that integrates three mixing mechanisms — convection, diffusion, and shearing — which enables the highly efficient and uniform mixing of powder materials. Through precise control of the internal motion trajectory of the mixer, it effectively enhances mixing performance and meets the process requirements of a wide range of industrial applications.

Detailed Introduction

- Add:

NO.3, Zhukeng Third Industrial Zone, Jinniu East Road, Pingshan District, Shenzhen

- Tel:

0755-89369630

- Mob:

400-822-5968

- E-mail:

brand@sz-manst.com

-

Wechat

Wechat -

Channels

Channels -

Duoyin

Duoyin