Dry Process Electrode Manufacturing System

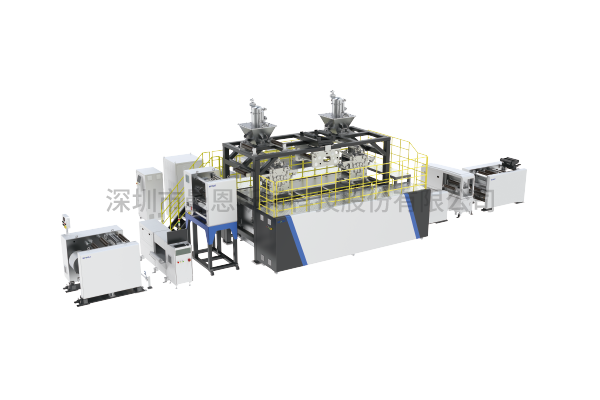

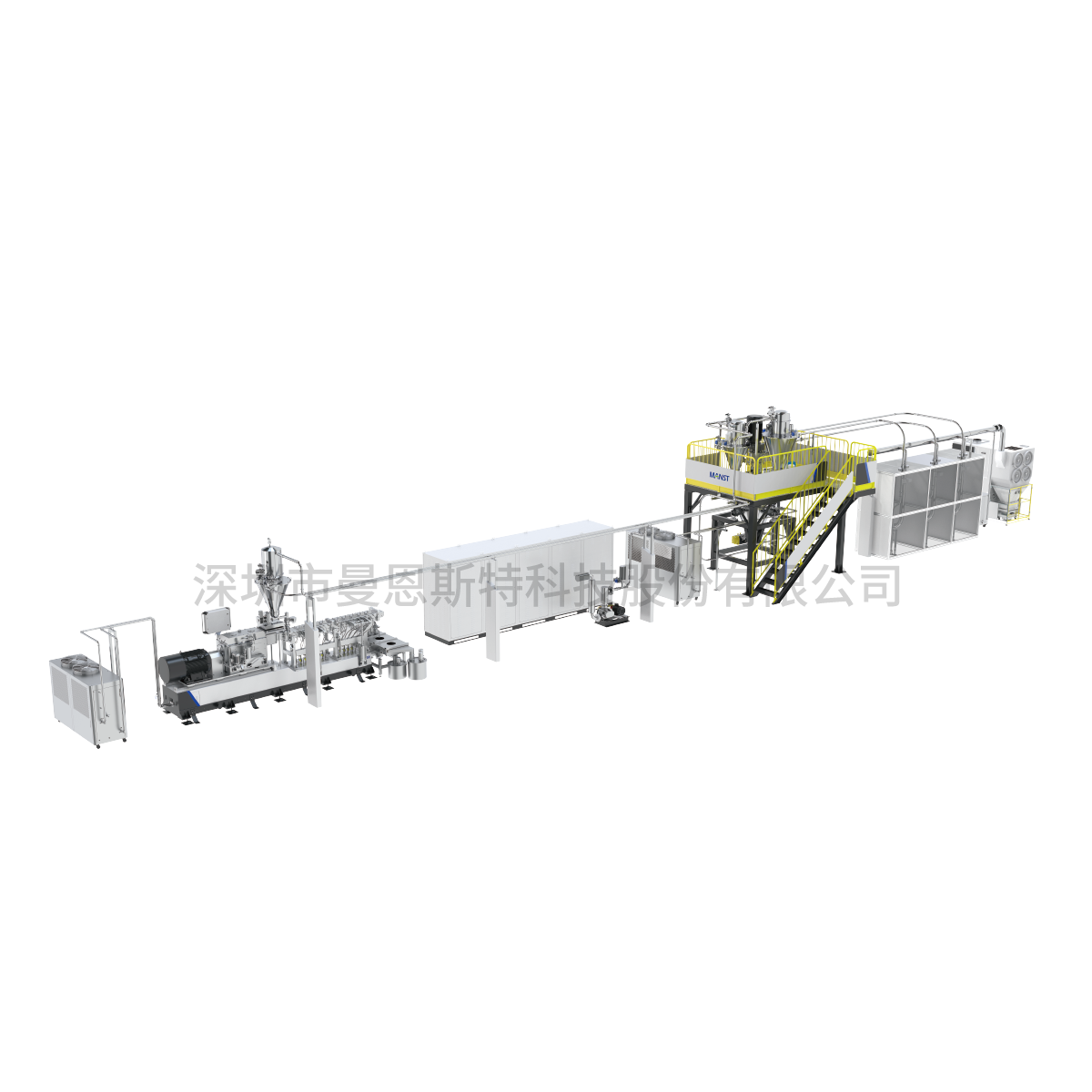

Dry Process Electrode Manufacturing SystemIntegrated Dry Electrode Manufacturing System incorporates powder processing and dual-sided multi-roll film forming/laminating subsystems, achieving fully automated production from raw materials to finished electrode sheets. The continuous process encompasses powder weighing & metering, mixing & pre-fibrillation, fibrillation, granulation, powder conveying & dosing, pre-forming, calendering (film thinning), lamination, and winding operations.

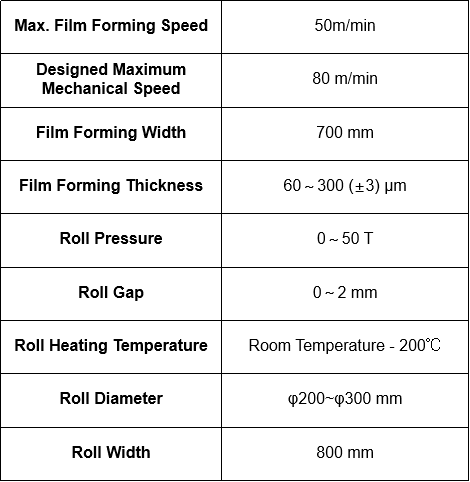

Multi-Roll Double-Sided Film Formation & Lamination SystemThe Dry Multi-Roll Double-Sided Film Formation & Lamination System utilizes an in-line, multi-roll calendering process, where a series of calender rolls work in sequence to progressively form and densify the film. Through precise control of roll gap, nip pressure, and temperature at each stage, the system achieves multi-stage calendering of film sheets. This process ensures precise control over final film thickness and compaction density, guaranteeing consistent product quality and adaptability to diverse production requirements.Detailed Introduction

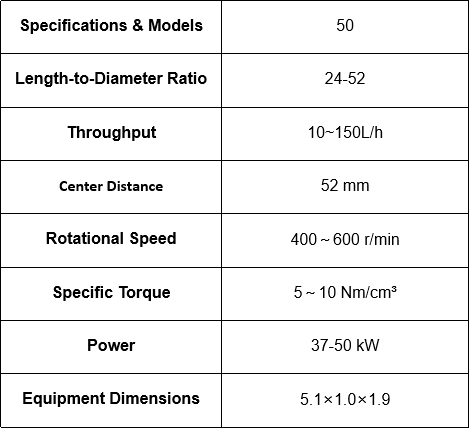

Multi-Roll Double-Sided Film Formation & Lamination SystemThe Dry Multi-Roll Double-Sided Film Formation & Lamination System utilizes an in-line, multi-roll calendering process, where a series of calender rolls work in sequence to progressively form and densify the film. Through precise control of roll gap, nip pressure, and temperature at each stage, the system achieves multi-stage calendering of film sheets. This process ensures precise control over final film thickness and compaction density, guaranteeing consistent product quality and adaptability to diverse production requirements.Detailed Introduction Dry Powder Handling SystemThe Dry Powder Processing System is a one-stop, fully automated powder handling solution covering the complete process — from powder feeding and gravimetric weighing to mixing, fiberillation, crushing, sieving - delivering finished fibrillation powder materials.Detailed Introduction

Dry Powder Handling SystemThe Dry Powder Processing System is a one-stop, fully automated powder handling solution covering the complete process — from powder feeding and gravimetric weighing to mixing, fiberillation, crushing, sieving - delivering finished fibrillation powder materials.Detailed Introduction