Filter Cartridge Filter BagManst Fluid Technology Co., Ltd. specializes in industrial environmental dust removal, solid-liquid separation, and filtration. Our main products include capsule filter cartridges, folding filter cartridges, wound filter cartridges, dust removal bags, etc. We can provide customers in various industries with comprehensive solutions for filtration, separation, and purification.

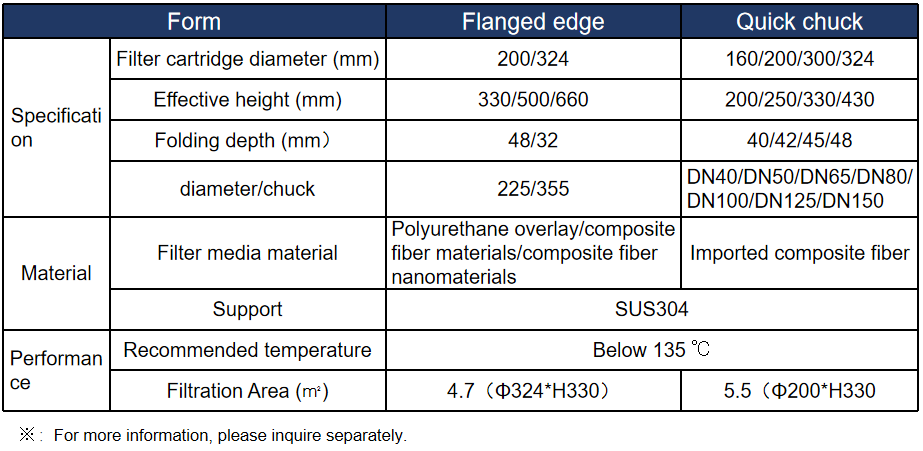

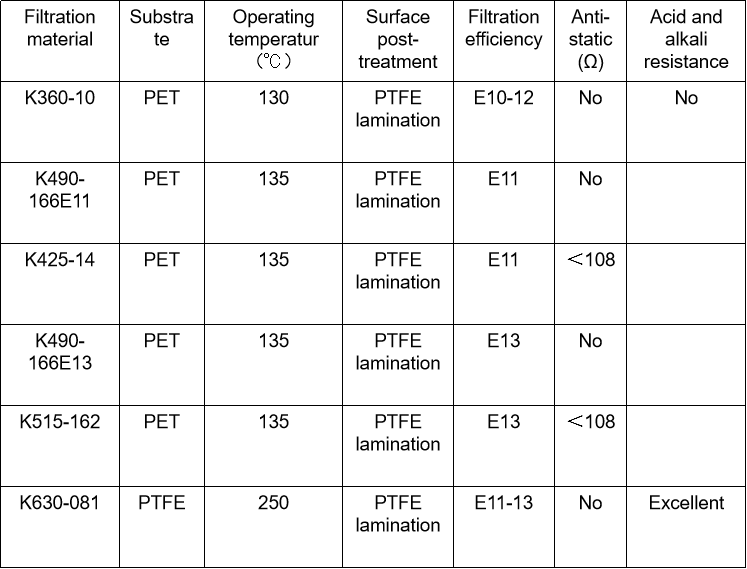

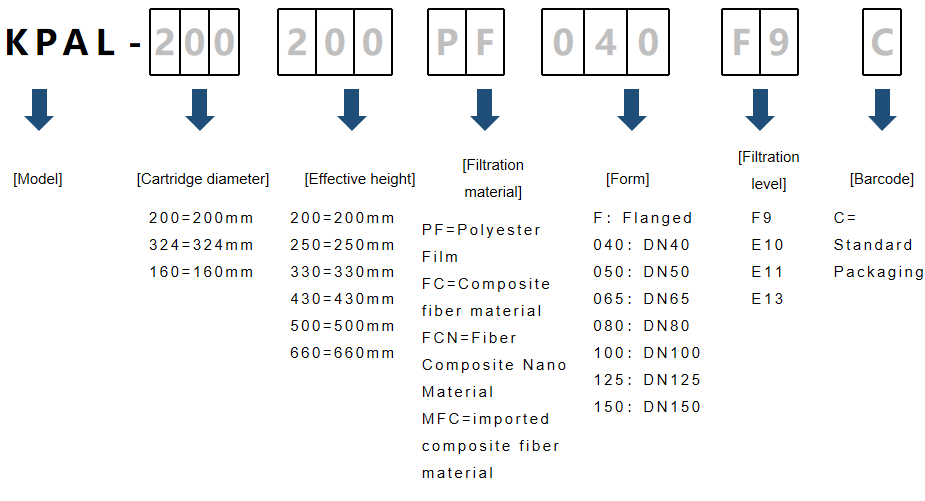

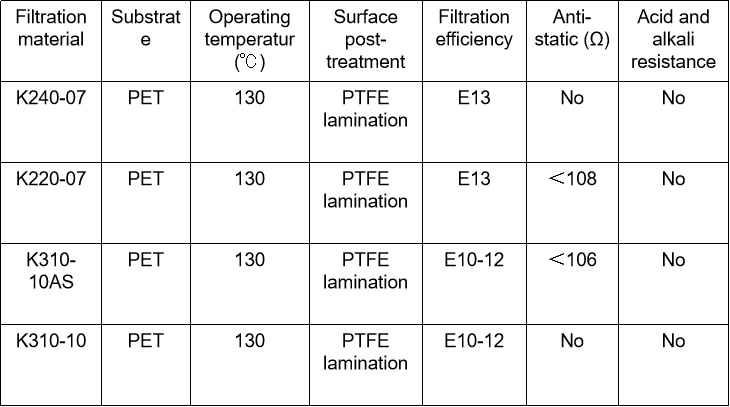

Filter Cartridge Filter BagManst Fluid Technology Co., Ltd. specializes in industrial environmental dust removal, solid-liquid separation, and filtration. Our main products include capsule filter cartridges, folding filter cartridges, wound filter cartridges, dust removal bags, etc. We can provide customers in various industries with comprehensive solutions for filtration, separation, and purification. KPAL SeriesKPAL cartridge series products are made of high-quality polyester base material with good fiber abrasion resistance, which makes the running resistance lower; PTFE coating technology makes the products have excellent chemical corrosion resistance, good oleophobic and hydrophobicity, and the filter cake formed by filtration is easier to be peeled off, soot cleaning is more thorough, and the running differential pressure is low.Detailed Introduction

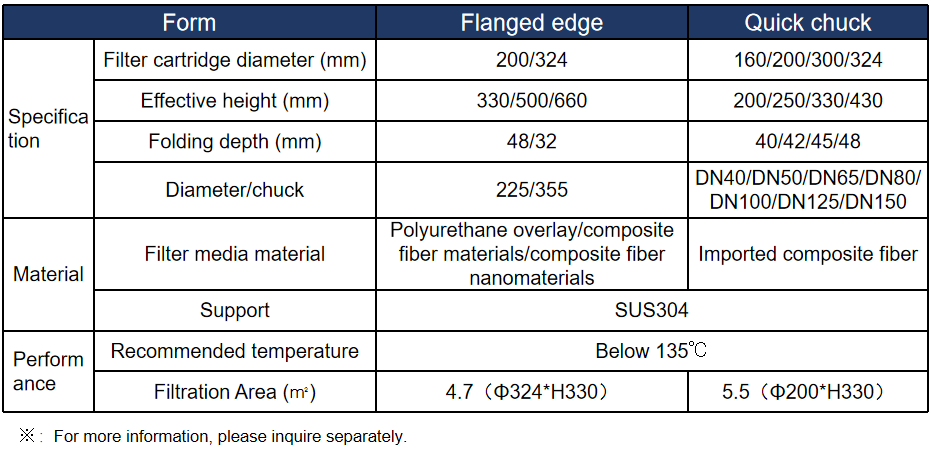

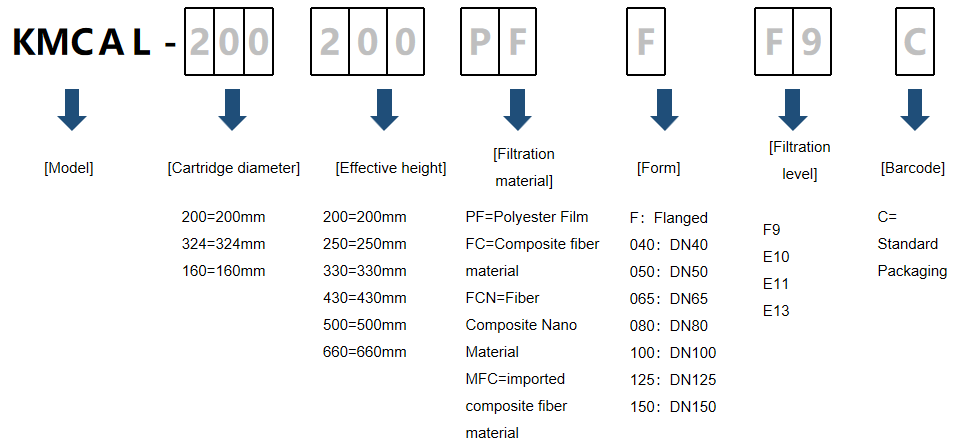

KPAL SeriesKPAL cartridge series products are made of high-quality polyester base material with good fiber abrasion resistance, which makes the running resistance lower; PTFE coating technology makes the products have excellent chemical corrosion resistance, good oleophobic and hydrophobicity, and the filter cake formed by filtration is easier to be peeled off, soot cleaning is more thorough, and the running differential pressure is low.Detailed Introduction KMCAL SeriesKMCAL cartridge series products are made of high-quality polyester base material with good fiber abrasion resistance, which makes the running resistance lower; PTFE coating technology makes the products have excellent chemical corrosion resistance, good oleophobic and hydrophobicity, and the filter cake formed by filtration is easier to be peeled off, soot cleaning is more thorough, and the running differential pressure is low.Detailed Introduction

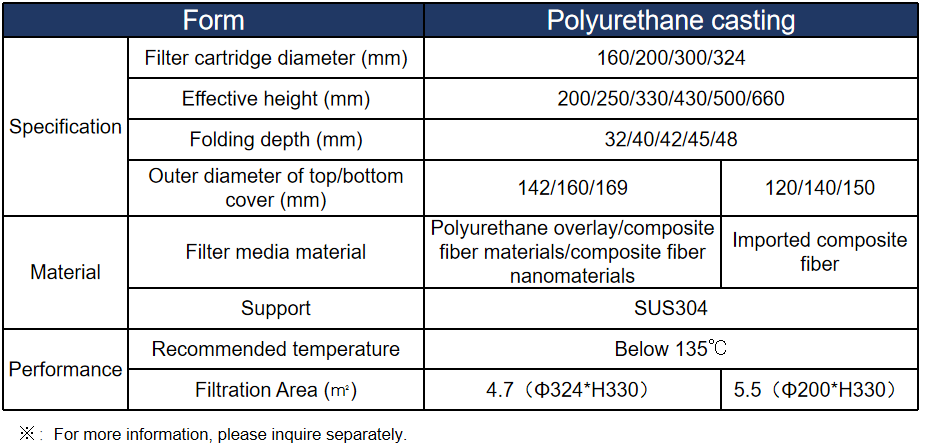

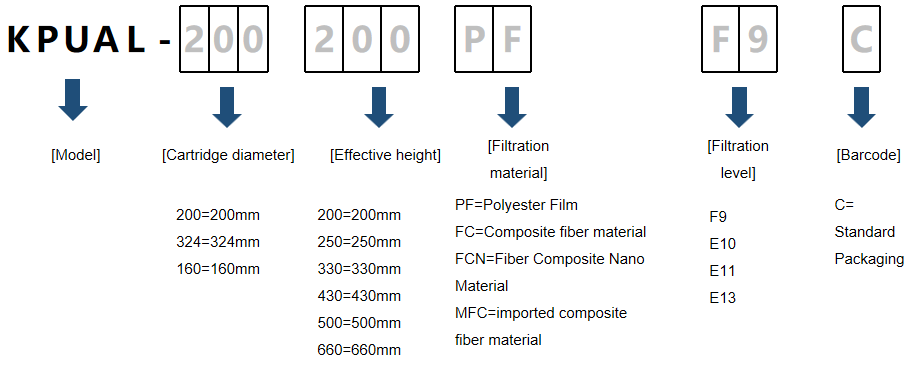

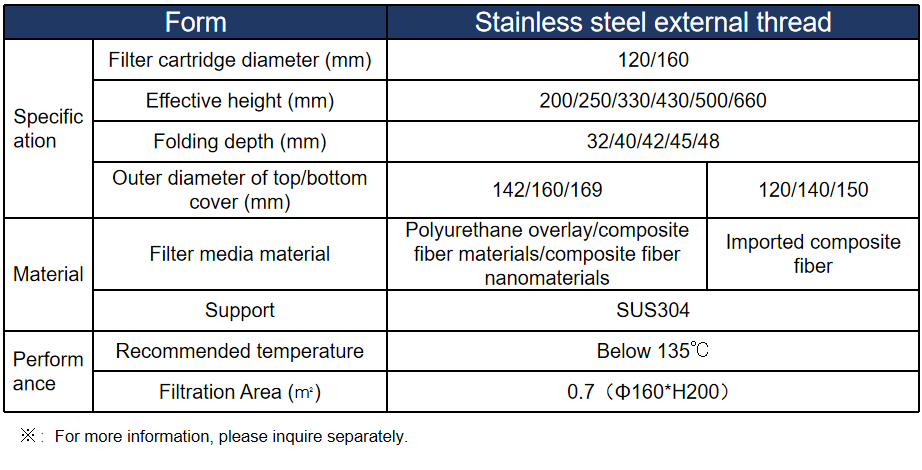

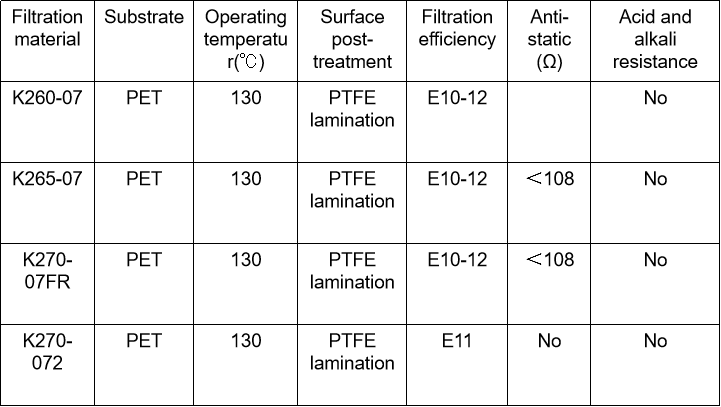

KMCAL SeriesKMCAL cartridge series products are made of high-quality polyester base material with good fiber abrasion resistance, which makes the running resistance lower; PTFE coating technology makes the products have excellent chemical corrosion resistance, good oleophobic and hydrophobicity, and the filter cake formed by filtration is easier to be peeled off, soot cleaning is more thorough, and the running differential pressure is low.Detailed Introduction KPUAL SeriesKPUAL type filter cartridge series products adopt polyurethane upper and lower end cap structure, which is easy to replace; high-quality polyester base material with good fiber abrasion resistance, which makes the operation resistance lower. PTFE coating technology makes the products have excellent chemical corrosion resistance, good oleophobic and hydrophobicity, and the filter cake formed by filtration is easier to be peeled off, soot cleaning is more thorough, and the running differential pressure is low.Detailed Introduction

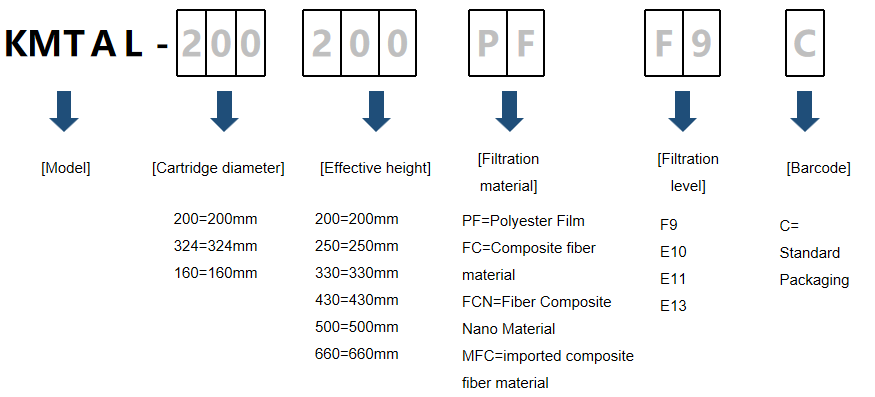

KPUAL SeriesKPUAL type filter cartridge series products adopt polyurethane upper and lower end cap structure, which is easy to replace; high-quality polyester base material with good fiber abrasion resistance, which makes the operation resistance lower. PTFE coating technology makes the products have excellent chemical corrosion resistance, good oleophobic and hydrophobicity, and the filter cake formed by filtration is easier to be peeled off, soot cleaning is more thorough, and the running differential pressure is low.Detailed Introduction KMTAL SeriesKMTAL filter cartridges are designed with stainless steel external threads for easy installation, reducing manual operation costs; high-quality polyester base material with good fiber abrasion resistance, resulting in lower operating resistance; PTFE coating technology makes the products have excellent chemical corrosion resistance, good oleophobic and hydrophobicity, and the filter cake formed by filtration is easier to be peeled off, soot cleaning is more thorough, and the running differential pressure is low.Detailed Introduction

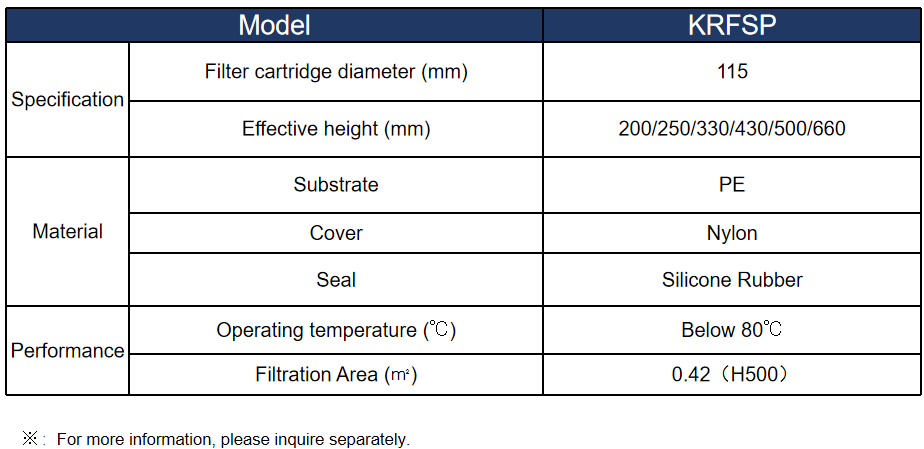

KMTAL SeriesKMTAL filter cartridges are designed with stainless steel external threads for easy installation, reducing manual operation costs; high-quality polyester base material with good fiber abrasion resistance, resulting in lower operating resistance; PTFE coating technology makes the products have excellent chemical corrosion resistance, good oleophobic and hydrophobicity, and the filter cake formed by filtration is easier to be peeled off, soot cleaning is more thorough, and the running differential pressure is low.Detailed Introduction KRFSP SeriesThe KRFSP series filter cartridges are produced using an integral molding plastic sintering process for the core material, providing a level of rigidity that other filter materials cannot achieve while withstanding higher filtration pressures. The optimized design reduces structural resistance, resulting in higher separation efficiency and extended service life.Detailed Introduction

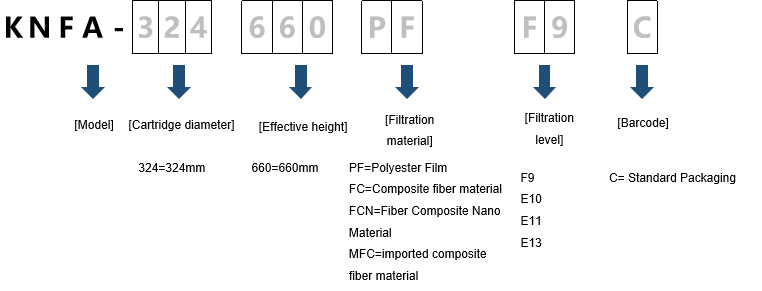

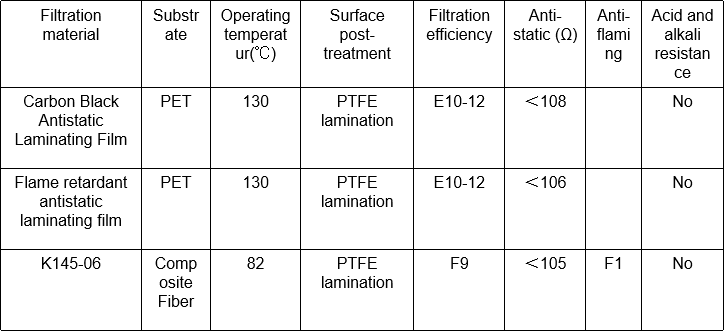

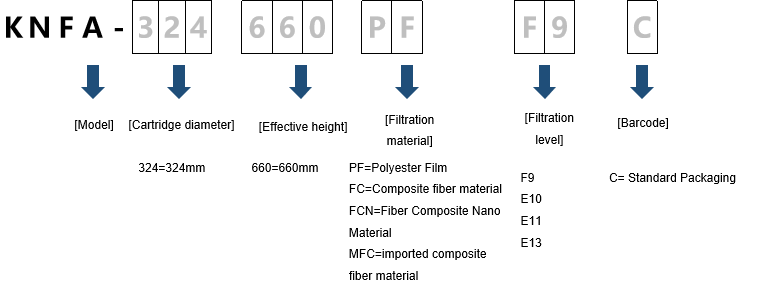

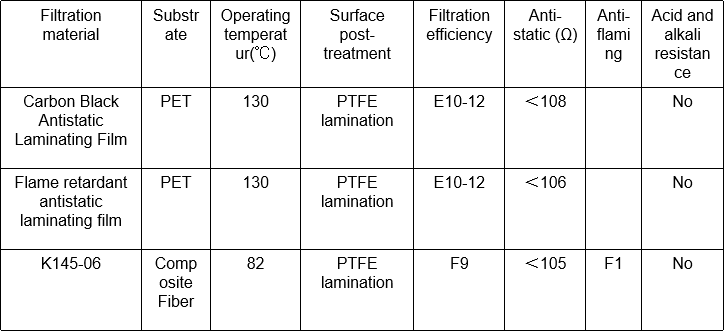

KRFSP SeriesThe KRFSP series filter cartridges are produced using an integral molding plastic sintering process for the core material, providing a level of rigidity that other filter materials cannot achieve while withstanding higher filtration pressures. The optimized design reduces structural resistance, resulting in higher separation efficiency and extended service life.Detailed Introduction KNFA SeriesThe KNFA series filter cartridge utilizes an outer layer of extremely fine elastic fiber web to prevent particle penetration into the filter cartridge base, thereby enhancing durability and reducing replacement costs. The imported nano flame-retardant and antistatic filter media improve filtration efficiency, achieving lower emission standards, and exhibiting lower initial resistance compared to other materials.Detailed Introduction

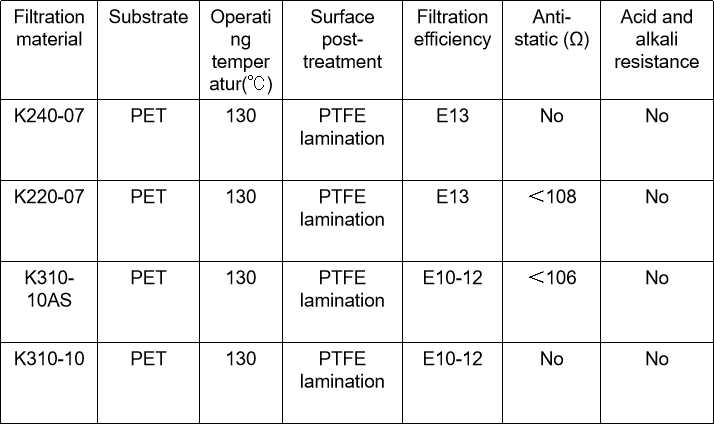

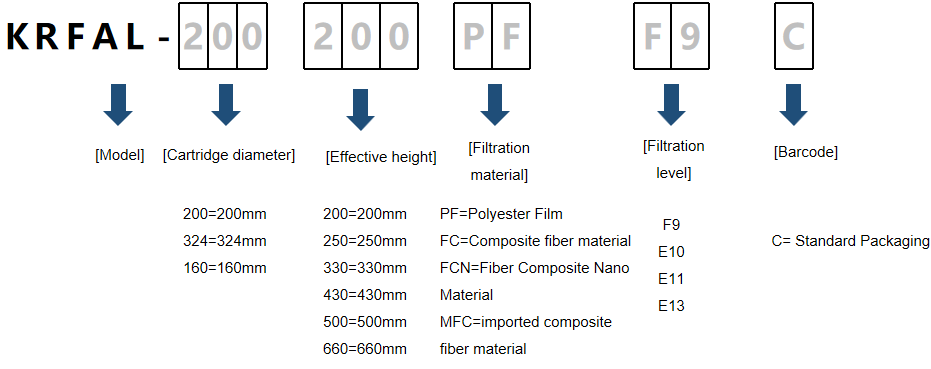

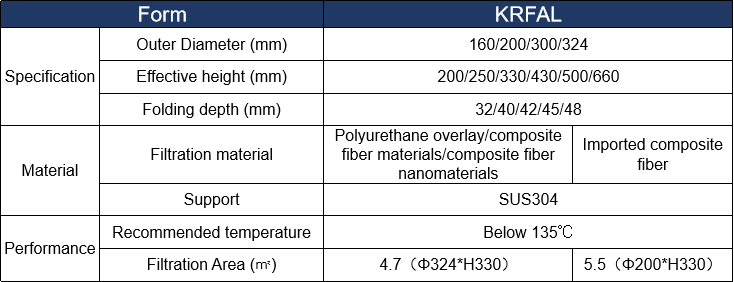

KNFA SeriesThe KNFA series filter cartridge utilizes an outer layer of extremely fine elastic fiber web to prevent particle penetration into the filter cartridge base, thereby enhancing durability and reducing replacement costs. The imported nano flame-retardant and antistatic filter media improve filtration efficiency, achieving lower emission standards, and exhibiting lower initial resistance compared to other materials.Detailed Introduction KRFAL SeriesThe KRFAL series filter cartridges are all made of high-quality polyester substrate, with excellent fiber abrasion resistance, resulting in lower operational resistance. The PTFE coating technology provides outstanding chemical corrosion resistance, excellent oil and water repellency, and easier cake release during filtration, ensuring more thorough dust cleaning and lower operating pressure drop.Detailed Introduction

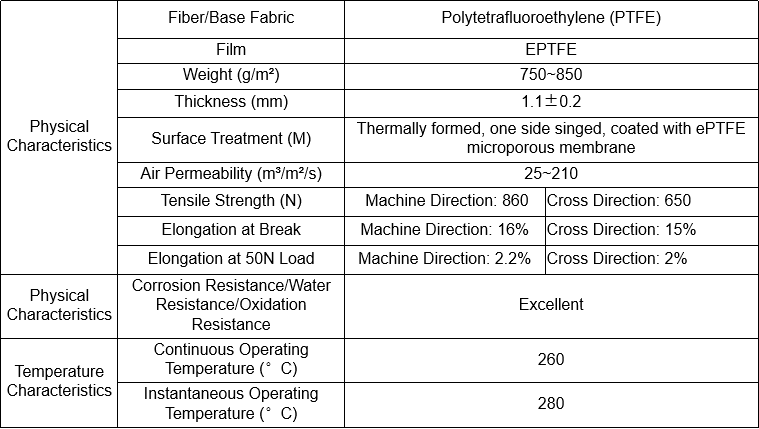

KRFAL SeriesThe KRFAL series filter cartridges are all made of high-quality polyester substrate, with excellent fiber abrasion resistance, resulting in lower operational resistance. The PTFE coating technology provides outstanding chemical corrosion resistance, excellent oil and water repellency, and easier cake release during filtration, ensuring more thorough dust cleaning and lower operating pressure drop.Detailed Introduction PTFE Needle-Punched FeltIt is a fiber with extremely stable chemical properties, made from imported fiber materials. It offers exceptional filtration efficiency. 100% PTFE needle-punched felt is primarily used in chemical industries, waste incineration, and high-temperature liquid filtration, while maintaining excellent chemical stability in various complex working conditions.Detailed Introduction

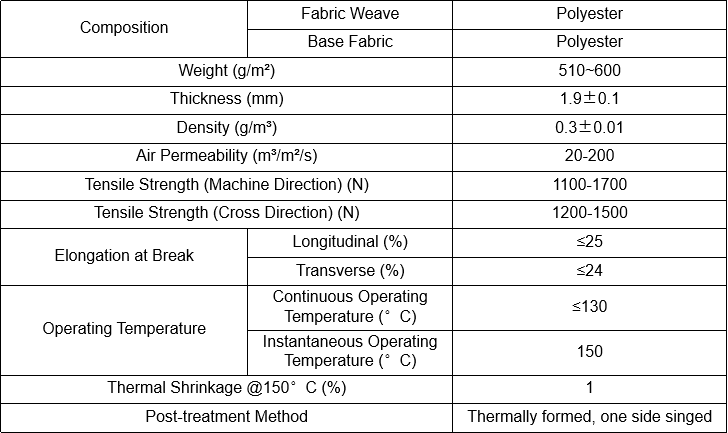

PTFE Needle-Punched FeltIt is a fiber with extremely stable chemical properties, made from imported fiber materials. It offers exceptional filtration efficiency. 100% PTFE needle-punched felt is primarily used in chemical industries, waste incineration, and high-temperature liquid filtration, while maintaining excellent chemical stability in various complex working conditions.Detailed Introduction Polyester Needle-Punched FeltIt features a smooth surface that effectively reduces flow resistance. The filter material, produced using easy-clean dust removal treatment technology, is dense yet breathable, exhibiting excellent dust removal performance.

Polyester Needle-Punched FeltIt features a smooth surface that effectively reduces flow resistance. The filter material, produced using easy-clean dust removal treatment technology, is dense yet breathable, exhibiting excellent dust removal performance.

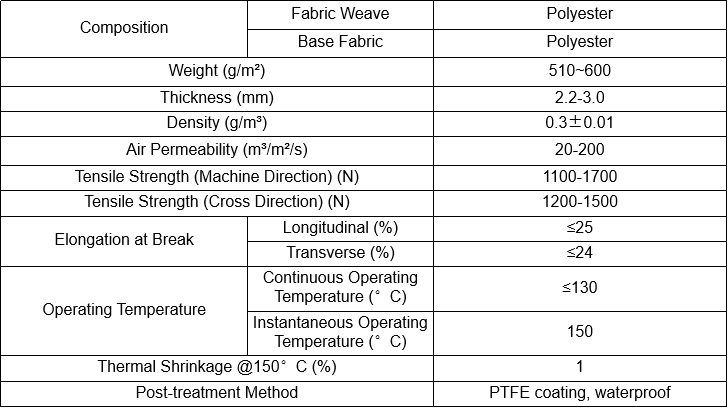

Detailed Introduction Waterproof and Oil-Resistant Needle-Punched FeltThe surface is highly effective in capturing dust particles, especially for wet and hygroscopic dust. It prevents bag clogging and performs exceptionally well in preventing condensation caused by high temperatures and humidity. It effectively prevents water and various oil contaminants from adhering and penetrating. Compared to regular filter materials, it not only possesses waterproof and oil-resistant properties but also exhibits excellent anti-adhesion and easy-stripping characteristics when it comes to dust particles.

Waterproof and Oil-Resistant Needle-Punched FeltThe surface is highly effective in capturing dust particles, especially for wet and hygroscopic dust. It prevents bag clogging and performs exceptionally well in preventing condensation caused by high temperatures and humidity. It effectively prevents water and various oil contaminants from adhering and penetrating. Compared to regular filter materials, it not only possesses waterproof and oil-resistant properties but also exhibits excellent anti-adhesion and easy-stripping characteristics when it comes to dust particles.

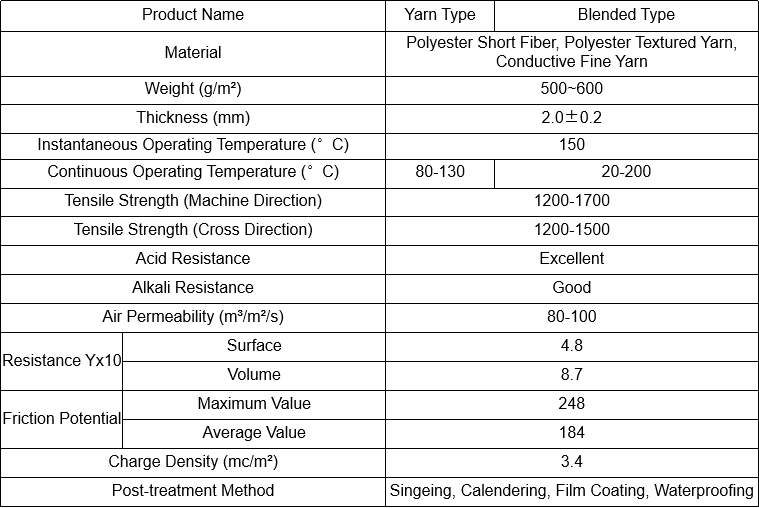

Detailed Introduction Anti-Static Needle-Punched FeltIt achieves excellent anti-static performance by controlling the base fabric and filter material of the filter bag and incorporating conductive fibers during the production process. It is suitable for use with flammable and explosive dust.

Anti-Static Needle-Punched FeltIt achieves excellent anti-static performance by controlling the base fabric and filter material of the filter bag and incorporating conductive fibers during the production process. It is suitable for use with flammable and explosive dust.

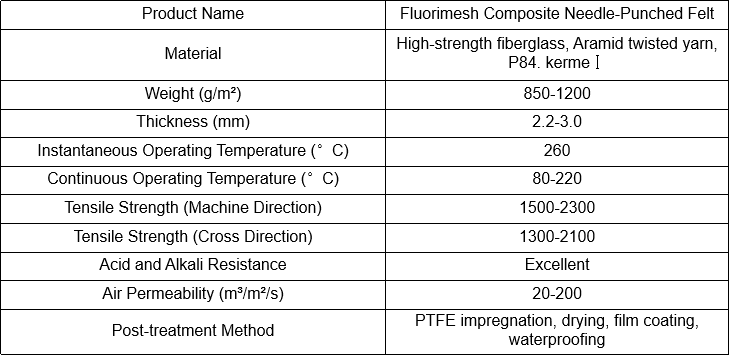

Detailed Introduction Fluorimesh Composite Needle-Punched FeltThis series is mainly made from high-strength fiberglass and P84.kerme I fibers, providing high wear resistance and high temperature resistance. It has a wide range of applications and is particularly suitable for the recovery and emission of industrial waste gases in steel plants, cement plants, gas facilities, and carbide factories.

Fluorimesh Composite Needle-Punched FeltThis series is mainly made from high-strength fiberglass and P84.kerme I fibers, providing high wear resistance and high temperature resistance. It has a wide range of applications and is particularly suitable for the recovery and emission of industrial waste gases in steel plants, cement plants, gas facilities, and carbide factories.

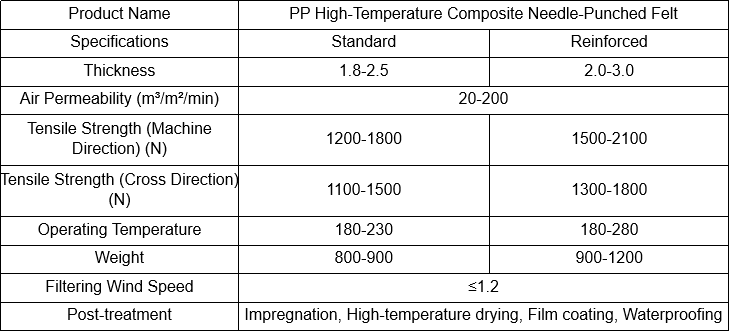

Detailed Introduction PP High-Temperature Composite Needle-Punched FeltThe series is primarily made from aromatic polyamide fibers and P84.kerme I fibers. It is characterized by high temperature resistance, high strength, corrosion resistance, and abrasion resistance. It is suitable for the recovery and emission of industrial exhaust gases from facilities such as gas plants, carbide factories, and cement plants.

PP High-Temperature Composite Needle-Punched FeltThe series is primarily made from aromatic polyamide fibers and P84.kerme I fibers. It is characterized by high temperature resistance, high strength, corrosion resistance, and abrasion resistance. It is suitable for the recovery and emission of industrial exhaust gases from facilities such as gas plants, carbide factories, and cement plants.

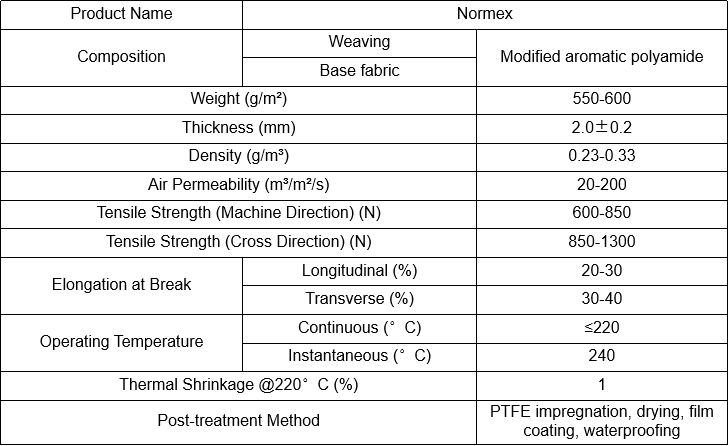

Detailed Introduction NormexThe Normex series is primarily made from imported fibers, providing excellent high-temperature resistance and acid-alkali resistance. These products are widely used in industries such as steel plants, cement plants, asphalt, and coking.

NormexThe Normex series is primarily made from imported fibers, providing excellent high-temperature resistance and acid-alkali resistance. These products are widely used in industries such as steel plants, cement plants, asphalt, and coking.

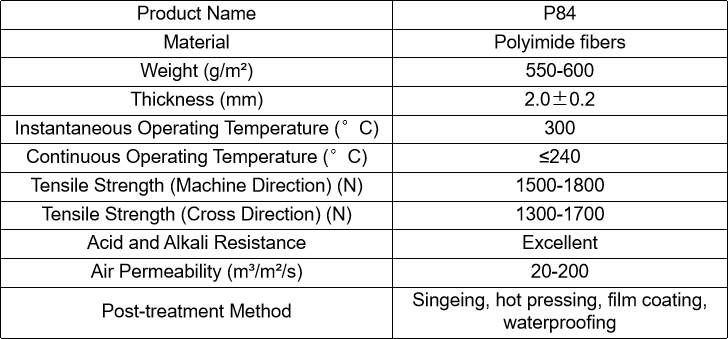

Detailed Introduction P84 Needle-Punched FeltIt is primarily made from polyimide fibers, providing excellent high-temperature resistance and acid-alkali resistance. It exhibits exceptional filtration performance for dust-laden gases with accompanying acid-alkali properties, making it particularly suitable for the waste incineration industry with high dust removal efficiency.Detailed Introduction

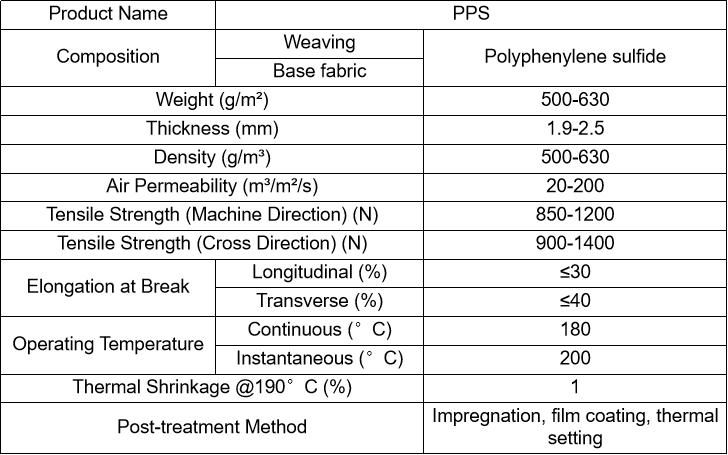

P84 Needle-Punched FeltIt is primarily made from polyimide fibers, providing excellent high-temperature resistance and acid-alkali resistance. It exhibits exceptional filtration performance for dust-laden gases with accompanying acid-alkali properties, making it particularly suitable for the waste incineration industry with high dust removal efficiency.Detailed Introduction PPS Needle-Punched FeltThe series is primarily made from polyphenylene sulfide fibers, providing excellent chemical resistance and demonstrating superior filtration performance even in harsh environments. It is extensively used in industries such as power plants, waste incineration, medical waste, and smelting.

PPS Needle-Punched FeltThe series is primarily made from polyphenylene sulfide fibers, providing excellent chemical resistance and demonstrating superior filtration performance even in harsh environments. It is extensively used in industries such as power plants, waste incineration, medical waste, and smelting.

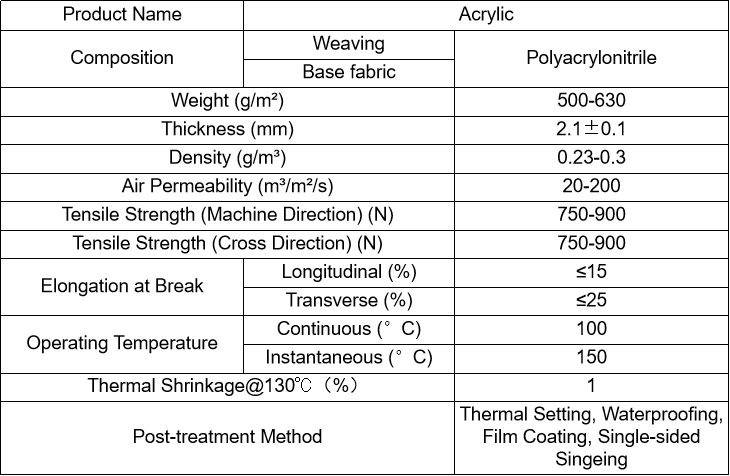

Detailed Introduction Acrylic Needle-Punched FeltThe series is primarily made from polyacrylonitrile fibers, providing excellent acid-alkali resistance and corrosion resistance against hydrochloric acid and phosphoric acid. Additionally, this material exhibits good resistance to hydrolysis, making it suitable for industries such as smelting, chemical, and power.Detailed Introduction

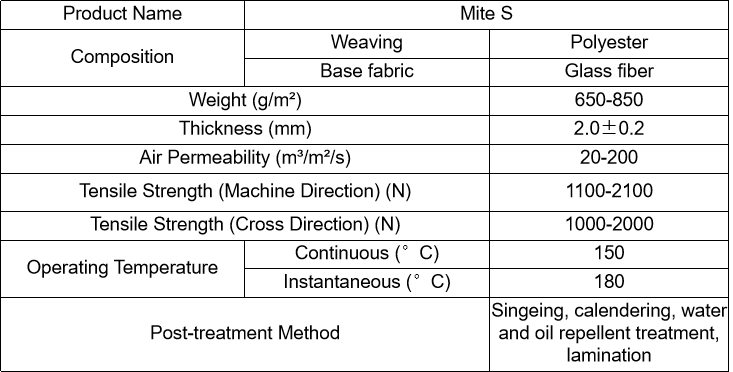

Acrylic Needle-Punched FeltThe series is primarily made from polyacrylonitrile fibers, providing excellent acid-alkali resistance and corrosion resistance against hydrochloric acid and phosphoric acid. Additionally, this material exhibits good resistance to hydrolysis, making it suitable for industries such as smelting, chemical, and power.Detailed Introduction Mite SThe series features a glass fiber woven fabric as the base fabric, providing high tensile strength and low elongation at break. It also exhibits minimal thermal shrinkage and moderate temperature resistance. Compared to standard temperature filter materials, it can withstand higher operating temperatures, significantly reducing operational costs.

Mite SThe series features a glass fiber woven fabric as the base fabric, providing high tensile strength and low elongation at break. It also exhibits minimal thermal shrinkage and moderate temperature resistance. Compared to standard temperature filter materials, it can withstand higher operating temperatures, significantly reducing operational costs.

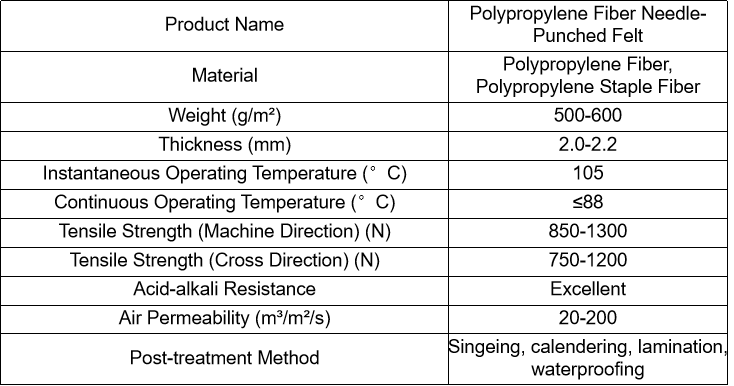

Detailed Introduction Polypropylene Fiber Needle-Punched FeltThe series is made from polypropylene fiber and is characterized by its lightweight and easy handling. It can be used in gas filtration or liquid-solid filtration applications with temperatures below 90°C or in environments with acid-alkali properties. It offers a high cost-performance ratio and has been widely adopted in industries such as steel, cement, petrochemicals, pharmaceuticals, and food.Detailed Introduction

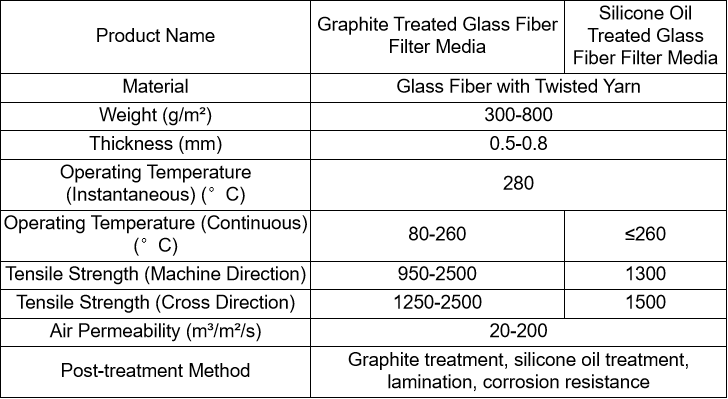

Polypropylene Fiber Needle-Punched FeltThe series is made from polypropylene fiber and is characterized by its lightweight and easy handling. It can be used in gas filtration or liquid-solid filtration applications with temperatures below 90°C or in environments with acid-alkali properties. It offers a high cost-performance ratio and has been widely adopted in industries such as steel, cement, petrochemicals, pharmaceuticals, and food.Detailed Introduction Glass Fiber Woven Filter MediaThe series is made from glass fiber as the raw material. It exhibits excellent high-temperature resistance, good air permeability, low filtration resistance, and has outstanding acid-alkali resistance. It offers a high cost-performance ratio and has been widely used in industries such as high-temperature smoke emissions, cement, and chemical smelting.Detailed Introduction

Glass Fiber Woven Filter MediaThe series is made from glass fiber as the raw material. It exhibits excellent high-temperature resistance, good air permeability, low filtration resistance, and has outstanding acid-alkali resistance. It offers a high cost-performance ratio and has been widely used in industries such as high-temperature smoke emissions, cement, and chemical smelting.Detailed Introduction