In the dry-process electrode manufacturing system for solid-state batteries, facing the challenges of high-solid-content, high-viscosity slurries, traditional equipment often suffers from issues like uneven dispersion, inaccurate temperature control, or unstable operation, which ultimately affect final product performance. The MANST VC High-Efficiency Mixer, through its dynamic design and mechanical structure, provides a reliable solution for electrode preparation by achieving micron-level uniform dispersion. It has become a key process unit driving the industrialization of solid-state batteries.

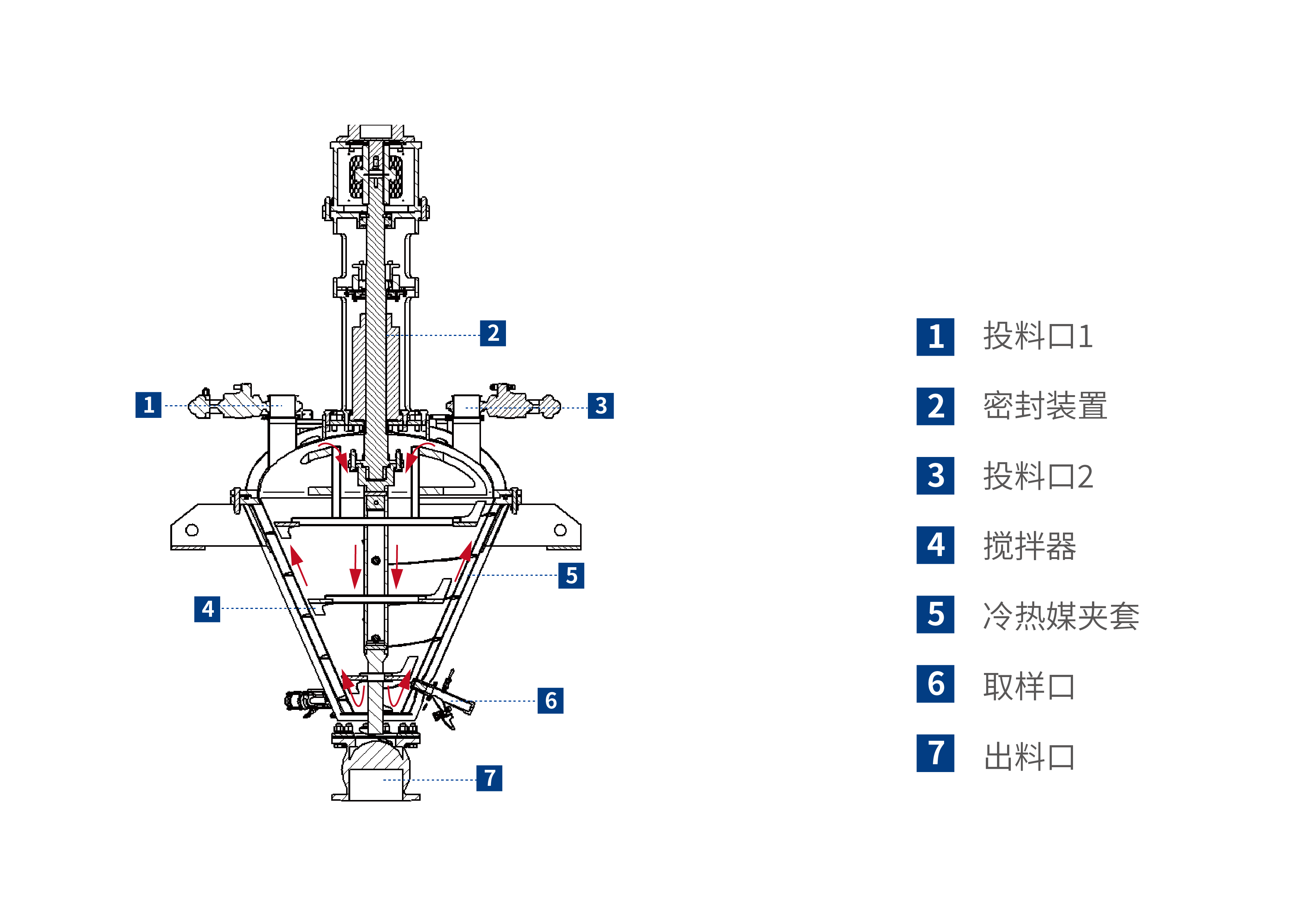

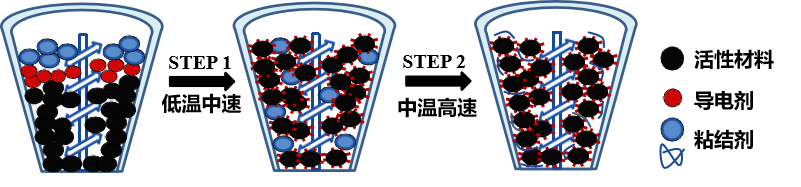

The working principle of the VC High-Efficiency Mixer is based on a precise dynamic circulation system of "centrifugal lifting – high-speed shearing – gravity fallback." The centrifugal force generated by the mixing paddle at the shaft center pushes materials toward the inner wall of the conical chamber. Coupled with the special shape of the blades on the mixing shaft, the materials are lifted upward. When passing through the high-speed fly knife assembly, the materials are subjected to instantaneous high shear forces, achieving effective deagglomeration and primary dispersion of clustered particles.

Subsequently, the materials fall back to the bottom of the chamber under gravity. During the descent, they pass through the high-speed blade area again, undergoing secondary mixing and refined dispersion. Ultimately, after multiple mixing cycles, the materials reach the mixed product quality required by customers.

The core advantage of the VC High-Efficiency Mixer lies in its dual-support main shaft structure and modular design. The dual-support system significantly suppresses deformation and vibration of the main shaft under high-speed, high-torque operating conditions from a mechanical perspective. This fundamentally eliminates the "sweeping" phenomenon, ensuring constant process clearance and mixing consistency. The optimized stress environment on the mechanical seal leads to significantly reduced wear, decreasing the equipment's overall failure rate by over 70%. Meanwhile, the mixing components adopt a graded, detachable modular design, reducing core maintenance time by over 90% and greatly enhancing equipment availability and production efficiency.

The VC High-Efficiency Mixer possesses excellent process adaptability and control capabilities. Its stirring linear speed can reach up to 30 m/s, and it can integrate customized high-speed fly knives, allowing flexible adjustment of shear intensity to meet different requirements from gentle mixing to intense dispersion. The conical chamber design balances discharge efficiency with cleaning convenience.

Furthermore, the working chamber enables precise temperature control management (range: 5–90°C, accuracy: ±3°C) and is compatible with various process requirements such as negative pressure, atmospheric pressure, and nitrogen-filled protection. This comprehensively accommodates material sensitivities to atmosphere and reaction temperature. Additionally, special coating treatments are applied to the inner walls and stirrer, effectively controlling magnetic impurities to meet the stringent cleanliness standards required for battery materials.

As the core equipment of the "mixing module" within MANST's overall dry-process electrode solution for solid-state batteries, the VC High-Efficiency Mixer serves the precise preparation of cathode/anode materials, solid electrolyte composite powders, and high-viscosity conductive slurries. Its processing capacity covers a wide range from 50L to 4000L, perfectly bridging the entire spectrum of needs from laboratory R&D, pilot testing, to large-scale production.

The MANST VC High-Efficiency Mixer is dedicated to enhancing product uniformity, production efficiency, and process controllability. It assists customers in addressing complex process requirements ranging from intensive mixing, dispersion, and crushing to drying, granulation, and coating, thereby accelerating the innovation and industrial implementation of next-generation battery technologies.

NO.3, Zhukeng Third Industrial Zone, Jinniu East Road, Pingshan District, Shenzhen

0755-89369630

400-822-5968

brand@sz-manst.com